Vibrating Screen

Introduction

Vibrating screen is a mechanical screening device that utilizes vibration to separate and classify materials of different sizes. It consists of a vibrating deck with strategically placed openings and a vibratory motor that imparts vibration to the deck. As a result, the material on the screen deck moves in a controlled manner, facilitating efficient separation and sizing.

Input Size: 0-400mm

Capacity: 7.5-700TPH

Material: Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore, coal and so on.

Product Description

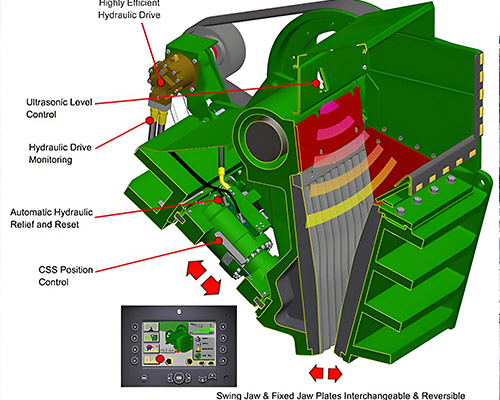

The vibrating screen is typically composed of the following components:

Screen Deck: This is the main working surface of the vibrating screen, where the material is placed for classification. It consists of a series of perforated plates, mesh, or bars, depending on the application requirements.

Vibratory Motor: The motor generates the vibratory motion that drives the material on the screen deck. It is typically mounted directly below the deck and connected via eccentric weights or magnetic drives.

Support Structure: The screen deck and motor are supported by a robust frame or structure designed to withstand the vibrating forces and ensure proper operation.

Screening Media: Various types of screening media, such as wire mesh, polyurethane, or rubber, can be used to enhance the screening efficiency and durability of the vibrating screen.

Working Principle

The vibrating screen operates on the principle of vibration-induced motion. The vibratory motor imparts rapid vibrations to the screen deck, causing the material to move across the deck in a controlled manner. The combination of vertical and horizontal movements creates a sieving action, allowing smaller particles to pass through the openings in the screen deck while larger particles are retained.

Application

The vibrating screen finds widespread applications in numerous industries, including:

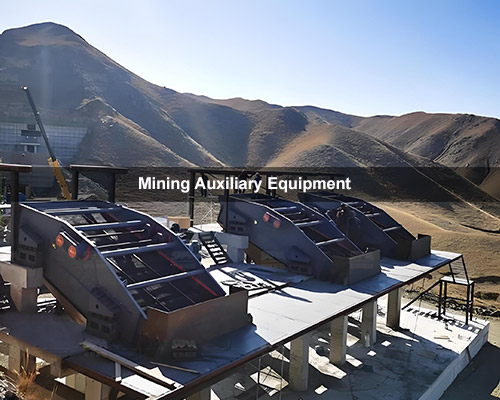

Mining and Quarrying: Used for screening and grading various minerals and aggregates.

Construction: Ideal for separating construction materials like sand, gravel, and crushed stones.

Chemical and Pharmaceutical: Suitable for classifying and filtering powders and granules.

Recycling: Efficiently separates recyclable materials, such as plastics, paper, and metals.

Food and Beverage: Used in the food processing industry for sieving and grading of ingredients.

Manufacturing: Helps in sorting and classifying materials during production processes.

Advantages

The vibrating screen offers several advantages, making it a preferred choice in many industries:

High Efficiency: The vibrating motion ensures rapid and efficient material separation, resulting in increased throughput and productivity.

Versatility: The ability to use different types of screening media allows the vibrating screen to handle a wide range of materials, from fine powders to coarse aggregates.

Easy Maintenance: The simple design and minimal moving parts of the vibrating screen make it easy to maintain and service, reducing downtime.

Customization: Vibrating screens can be customized to meet specific application requirements, including screen size, inclination, and screening media selection.

Cost-Effective: The vibrating screen’s reliability, long lifespan, and low operating costs contribute to its cost-effectiveness over time.

Product Parameters