VSI6X Series Vertical Shaft Impact Crusher

Introduction:

The VSI6X Series Vertical Crusher is a state-of-the-art crushing machine designed and developed by leading experts in the field. It combines the principles of stone-on-stone and stone-on-iron crushing, ensuring efficient and high-quality crushing operations. With its advanced technology and innovative design, the VSI6X Series Vertical Crusher has gained significant popularity in the industry.

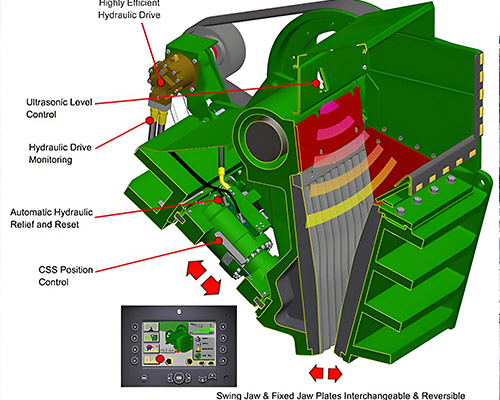

The VSI6X Series Vertical Crusher is characterized by its vertical shaft impact crushing technology, which utilizes a high-speed rotor with wear-resistant tips. It adopts a deep cavity-type rotor design, allowing larger throughput capacity and improved crushing efficiency. The crusher also features a modular design, offering flexibility for easy maintenance and component replacement.

Input Size: 0-50mm

Capacity: 100-800TPH

Material: Granite, quartz, basalt, pebble, limestone, dolomite, etc.

Working Principle:

The working principle of the VSI6X Series Vertical Crusher revolves around the “stone-on-stone” and “stone-on-iron” crushing modes. In the stone-on-stone crushing mode, the materials are crushed by mutual impact between the high-speed rotor and the crushing cavity. In the stone-on-iron crushing mode, the materials are crushed by the impact of the high-speed rotor against the anvils or impact blocks. This dual-crushing mode ensures excellent particle shape and consistent product gradation.

Applications:

The VSI6X Series Vertical Crusher finds extensive applications in various industries, including but not limited to:

1. Construction Aggregates: The crusher efficiently produces high-quality aggregates for use in road construction, railway ballast, concrete production, and other construction projects.

2. Mineral Processing: It is suitable for crushing various minerals, such as limestone, granite, basalt, and ores like iron ore and copper ore, facilitating the production of fine and uniform mineral particles.

3. Industrial Minerals: The VSI6X crusher is effective in processing industrial minerals like quartz, feldspar, and mica, providing consistent sizing and shape control for different applications.

4. Recycling: It can process and crush recycled materials, including concrete, asphalt, and demolition waste, contributing to the sustainable utilization of resources.

Advantages:

The VSI6X Series Vertical Crusher offers several notable advantages, making it a preferred choice in the market:

1. High Crushing Efficiency: The optimized crushing chamber design and high-speed rotor contribute to improved crushing efficiency, resulting in higher throughput and reduced energy consumption.

2. Excellent Particle Shape: The crusher’s stone-on-stone and stone-on-iron crushing modes ensure superior particle shape, enhancing the quality of final products.

3. Adjustable Configuration: The modular design allows for easy customization and adjustment of the crusher’s configuration to meet specific production requirements.

4. Easy Maintenance: The VSI6X crusher features a user-friendly design for convenient maintenance and quick replacement of wearing parts, minimizing downtime.

5. Advanced Safety Features: The crusher incorporates advanced safety features to ensure operator safety and protect the equipment from damage.

Product Parameters