Cost of 200 TPH Granite Crushing Plant

Investing in a medium-scale aggregate project is a significant financial commitment. For quarry owners and contractors, determining the cost of a 200 tph granite crushing plant is often the first step in feasibility analysis. However, the initial purchase price is only the tip of the iceberg. Granite is an igneous rock with high hardness and high abrasiveness (silica content), which means choosing the wrong equipment can lead to skyrocketing wear costs later.

At Liming Heavy Industry, we don’t just sell machines; we design high-efficiency production lines that lower your cost per ton. Whether you are in Nigeria, the Philippines, or Chile, this guide will break down the pricing factors, the ideal equipment configuration for granite, and how to maximize your return on investment (ROI).

What Factors Determine the Cost of a 200 TPH Granite Crushing Plant?

There is no single “sticker price” for a crushing plant because the solution must be customized to your specific mining site. The total cost typically ranges widely based on three core variables:

- Raw Material Size (Feed Size): If your blasted granite rocks are larger than 600mm, you require a larger, heavy-duty primary jaw crusher, which increases the initial investment but reduces blasting costs.

- Output Requirement (Aggregate Sizes): Producing a simple mix (e.g., 0-40mm) is cheaper than producing multiple calibrated sizes (e.g., 0-5mm, 5-10mm, 10-20mm) which requires additional vibrating screens and conveyors.

- Configuration Type (Stationary vs. Mobile):

- Stationary Plants: Lower initial equipment cost, but require concrete foundations and installation time. Ideal for long-term quarries.

- Mobile Crushing Stations: Higher initial purchase price, but zero installation cost and high mobility. Ideal for contractors moving between sites.

Recommended Configuration: Why “Jaw + Cone” is Essential for Granite

Granite is a hard rock. While Impact Crushers are cheaper initially, their wear parts (blow bars) wear out very quickly when processing granite, leading to high operational costs (OPEX). For a 200 TPH granite crushing plant, Liming Heavy Industry recommends a two-stage crushing process involving a Jaw Crusher and a Cone Crusher.

Stage 1: Primary Crushing – PE Series Jaw Crusher

The granite is fed into the PE Series Jaw Crusher via a vibrating feeder. This machine handles the coarse crushing, reducing large boulders into manageable sizes (roughly 150mm-300mm).

- Model Recommendation: PE-750×1060

- Advantage: High crushing ratio and deep crushing cavity.

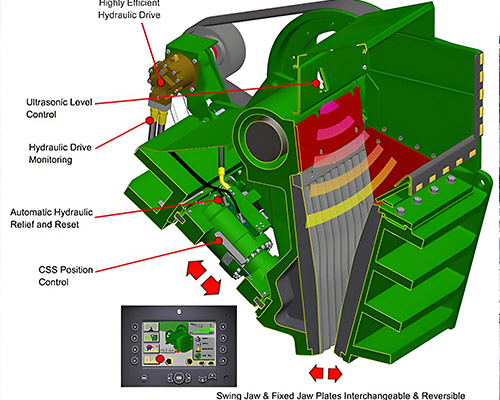

Stage 2: Secondary Crushing – HST/HPT Hydraulic Cone Crusher

This is the core of the granite solution. The Cone Crusher uses a lamination crushing principle, which is perfect for hard rocks. It produces cubic shapes with minimal wear compared to impact crushers.

Standard Equipment List for 200 TPH Granite Line

| Equipment Type | Model | Function |

|---|---|---|

| Vibrating Feeder | GZD Series | Uniformly feeds material into the primary crusher. |

| Primary Crusher | PE-750×1060 Jaw Crusher | Coarse crushing of large granite stones. |

| Secondary Crusher | HST160 or HPT300 Cone Crusher | Fine crushing; ensures good particle shape. |

| Vibrating Screen | 3YZS1860 | Separates final aggregates into different sizes. |

| Auxiliary | Belt Conveyors & Control Panel | Material transport and electric control system. |

Profitability Analysis: Balancing Cost vs. Value

When calculating the cost of a 200 tph granite crushing plant, you must look at the long-term ROI. A Liming Cone Crusher solution might cost slightly more upfront than a generic impact crusher setup, but the savings in wear parts usually pay for the difference within 6 months of operation.

Example Case: A client in Southeast Asia switched from a local impact crusher to a Liming HST Single Cylinder Cone Crusher for their 200 TPH granite line. Result: Wear part costs dropped by 40%, and the final aggregate shape met the strict standards for high-grade highway concrete.

Frequently Asked Questions (FAQ)

1. What is the estimated price range for a 200 TPH granite crushing plant?

The price generally ranges from $200,000 to $550,000 USD depending on whether you choose a stationary or mobile setup, and the specific models of cone crushers (HST vs. Py series). For an accurate quote, please contact our engineering team.

2. Can I use an Impact Crusher for granite to save money?

Technically yes, but it is not recommended for long-term operations. Granite is highly abrasive. Using an Impact Crusher will result in frequent downtime for replacing blow bars, ultimately making the operational cost much higher than using a Cone Crusher.

3. How much power does a 200 TPH plant require?

A standard 200 TPH stationary granite line typically requires an installed power of approximately 250kW to 350kW. Liming provides optimized electric control cabinets to ensure energy efficiency.

Get Your Customized Quote Today

Don’t let the complexity of equipment selection delay your project. Liming Heavy Industry has helped thousands of customers set up profitable crushing plants globally.

Want to know the exact cost of a 200 tph granite crushing plant tailored to your site? Click the button below to speak with our experts.