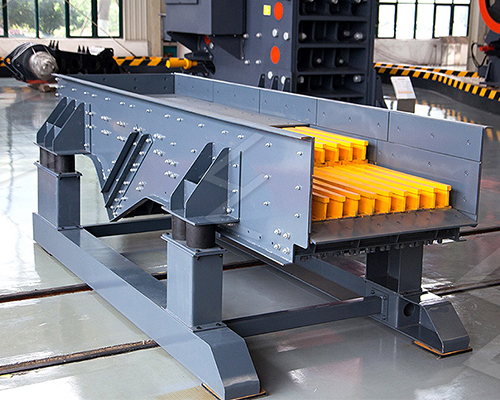

GF Series Vibrating Feeder

GF Series Vibrating Feeder is a light and efficient feeder specially manufactured for mobile crusher. It can match with Jaw Crusher, Primary Impact Crusher and Hammer Crusher, etc.Traditional methods of material transport often face challenges related to uneven feeding, low feeding capacity, and excessive energy consumption. Liming Heavy Industry recognized these issues and introduced the GF Series Vibrating Feeder, aiming to address these concerns and provide an innovative solution.

Input Size: 0-700mm

Capacity: 280-450TPH

Material: Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore and so on.

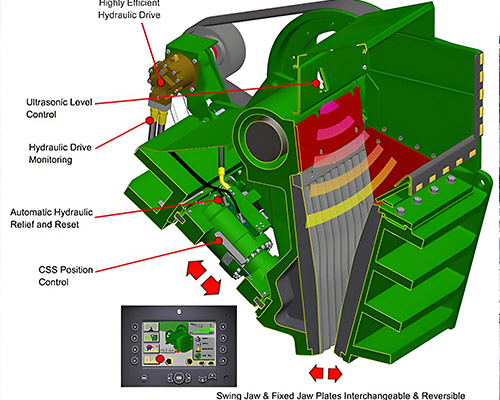

Key Features and Working Principle

GF Series Vibrating Feeder incorporates advanced technology and engineering excellence to deliver exceptional performance. Its key features include:

- a. High feeding capacity: The feeder is designed to handle large volumes of materials, ensuring uninterrupted feeding for various applications.

- b. Smooth and uniform feeding: The vibrating feeder uses a vibrating motor to generate linear motion, resulting in smooth and uniform material flow.

- c. Adjustable feeding speed: Operators can easily adjust the feeding speed to match the processing capacity and specific requirements of different materials.

- d. Stable and reliable operation: The feeder is equipped with reliable components and a robust structure to ensure long-term, trouble-free operation.

- e. Low power consumption: Through innovative design and energy-efficient components, the GF Series Vibrating Feeder minimizes power consumption, contributing to sustainable operations.

Advantages and Benefits

GF Series Vibrating Feeder offers several advantages over conventional feeding methods:

- a. Enhanced efficiency: With its high feeding capacity and adjustable feeding speed, the feeder optimizes material flow, improving overall operational efficiency.

- b. Reduced downtime: The stable and reliable operation of the feeder minimizes downtime and maintenance requirements, maximizing productivity.

- c. Improved equipment lifespan: By providing a consistent and controlled flow of materials, the feeder reduces the wear and tear on downstream equipment, extending their lifespan.

- d. Energy savings: The low power consumption of the GF Series Vibrating Feeder reduces energy costs and environmental impact, aligning with sustainability goals.

- e. Versatile applications: The feeder is suitable for a wide range of industries and materials, including ores, aggregates, coal, and chemicals, enhancing its versatility and usability.

Case Studies

This section presents real-world case studies that demonstrate the effectiveness of the GF Series Vibrating Feeder in various applications. The studies highlight how the feeder improved productivity, reduced operational costs, and enhanced overall process efficiency.

Product Parameters