Raymond Mill

Raymond Mill, also known as Raymond roller mill, is a widely utilized grinding equipment in the mining, construction, and chemical industries.Raymond Mill has gained significant popularity in various industries due to its efficient grinding capabilities. It plays a crucial role in the production of fine powder materials and has been widely used in mining, construction, metallurgy, and chemical industries.The Raymond Mill is a grinding machine, suitable for the preparation of various kinds of mineral powder and coal powder preparation.

Input Size: 15-25mm

Capacity: 0.6-4.5TPH

Material: Barite, calcite, potash feldspar, talc, marble, limestone, dolomite, fluorspar, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, etc.

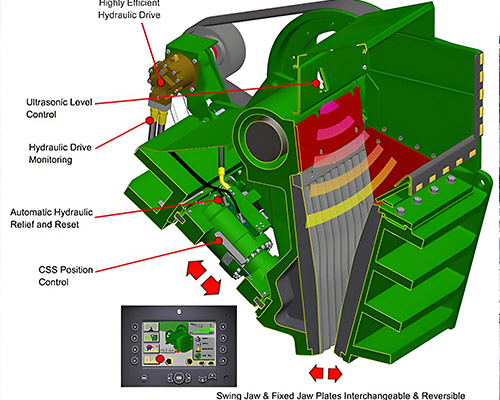

Key Features and Working Principle:

Raymond Mill incorporates several key features that contribute to its efficiency. These include a high-quality grinding roller assembly, a powerful grinding system, and an advanced classification system. The mill operates based on the principle of grinding and impact, where the grinding roller and grinding ring apply pressure and crush the material. The crushed material is then transported to the classifier, which separates the fine powder from the coarse particles.

Advantages and Benefits:

Raymond Mill offers numerous advantages over other grinding mills. Firstly, it has a high grinding efficiency, allowing for the production of finer particles with reduced energy consumption. Secondly, the mill has a wide range of application capabilities, making it suitable for grinding various materials, including minerals, chemicals, and ores. Additionally, Raymond Mill has a compact structure, low maintenance requirements, and easy operation, which further enhance its practicality.

Applications:

Raymond Mill finds extensive applications in various industries. In the mining industry, it is used for grinding minerals and ores, such as limestone, gypsum, and talc. In the chemical industry, Raymond Mill is employed for processing chemicals and pigments. Furthermore, it is utilized in the construction industry for grinding materials like cement clinker and concrete.

Performance Metrics and Future Prospects:

The performance of Raymond Mill can be evaluated based on several key metrics, including grinding efficiency, energy consumption, and product fineness. Ongoing research and development efforts focus on improving the mill’s performance, optimizing its operation, and reducing environmental impacts. Future prospects include the integration of advanced control systems and automation technologies to enhance productivity, precision, and sustainability.

Product Parameters