VU Tower-like Sand-making System

Rapid urbanization and population growth drive the need for new buildings and infrastructure, making sand a high-demand commodity. Manufacturing sand is a way to preserve natural riverbanks and shorelines where sand would otherwise be extracted, reduce energy consumption, and utilize aggregate waste as a raw material for sellable product.

To overcome unreasonable grading, excessive powder content and silt content and unqualified grain shape of traditional machine-made aggregate on the market, Liming Heavy Industry pushes out the VU Tower-like Sand-making System. The aggregate produced always features excellent quality and the production process produces no sludge, waste water or dust, completely meeting the requirements for environmental protection.

Liming Heavy Industry’s indigenously designed and developed Sand Crusher to meet the increased demand of fine M sand and plaster sand. Liming Heavy Industry is supplying sand plants from capacity 100-300 TPH.

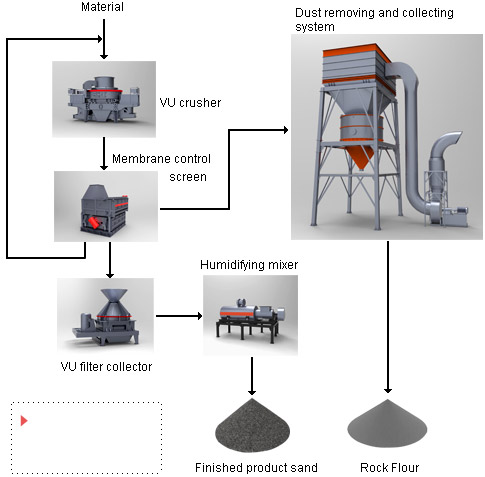

Production Process Flow

Liming Heavy Industry VU dry process of sand and gravel aggregate system with the most reasonable, greatest degree reproduce naturally in the process of natural sand formed broken, erosion action such as friction, natural washing, make product sand performance is improved. – 15 mm raw materials (can be stone chips, pea stone and other cheap accessible raw materials such as stone) after dealing with the VU system is reasonable and efficient, reasonable distribution, grain output fruity, controllable sand powder content, as well as dry clean, can undertake unity recycled high value-added powder (determined according to the raw material can be used).

Technical Parameters

| Model | Parameter Name | ||||

| Feeding Size(mm) | Raw Material Feeding (t/h) | Capacity(t/h) | Powder Content (adjustable) | Installed Power(Kw) | |

| VU-120 | 0-15 | 90-110 | 75-95 | 3-15% | ≈780 |

| VU-150 | 0-25 | 135-150 | 110-135 | 3-15% | ≈920 |

| VU-300 | 0-25 | 270-300 | 220-270 | 3-15% | ≈1960 |