LM Vertical Mill

LM Vertical Mill, developed by advanced engineering techniques, has garnered significant attention for its ability to address these challenges effectively. Based on the absorption of advanced technologies of famous international corporations and 30 years’ experience in grinding mill production, Liming Heavy Industry has launched the LM Vertical Grinding Mill which integrates five functions of crushing, grinding, powder selection, drying and material conveying. It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protection.

Input Size: 0-70mm

Capacity: 10-320TPH

Material: Limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc.

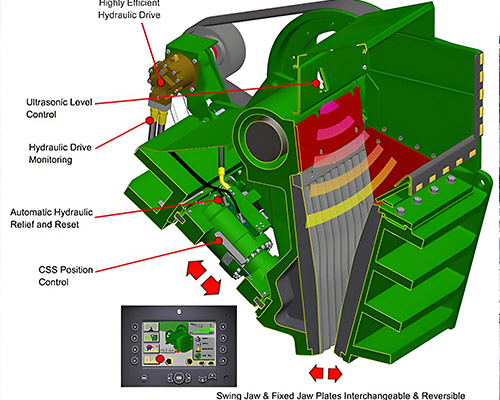

Design and Functionality

LM Vertical Mill boasts a unique design that sets it apart from traditional grinding mills. Its vertical configuration allows for efficient material handling and grinding operations. Equipped with a high-speed rotor and precision grinding rollers, the LM Vertical Mill ensures precise and uniform grinding performance. The mill’s compact structure and integrated design facilitate easy installation and maintenance.

Operational Advantages

- 1. Enhanced Efficiency: The LM Vertical Mill optimizes grinding processes, enabling higher production rates and improved product quality. Its advanced control system enables precise adjustments, minimizing energy consumption and maximizing output.

- 2. Versatility: The LM Vertical Mill can handle a wide range of materials, including minerals, ores, and various industrial byproducts, making it suitable for diverse industries such as cement, mining, and power generation.

- 3. Reduced Downtime: The vertical design of the mill allows for quick and easy maintenance and replacement of parts, reducing downtime and increasing overall productivity.

Environmental Benefits

- 1. Energy Efficiency: The LM Vertical Mill incorporates advanced technologies, such as low-resistance design and efficient classifiers, resulting in reduced energy consumption during grinding operations. This translates into lower carbon emissions and a smaller environmental footprint.

- 2. Waste Utilization: The LM Vertical Mill can effectively grind and process industrial byproducts, such as slag and fly ash, enabling their utilization as supplementary cementitious materials. This promotes sustainable waste management and reduces the need for virgin raw materials.

- 3. Noise and Dust Reduction: The vertical configuration of the mill, along with its integrated dust collection system, minimizes noise and dust emissions, creating a healthier and safer working environment.

Applications in Various Industries

LM Vertical Mill finds extensive applications in numerous industries, including cement production, mining, metallurgy, chemical processing, and power generation. Its versatility and efficiency make it an ideal choice for grinding different materials, achieving higher productivity, and meeting stringent quality standards.

Product Parameters