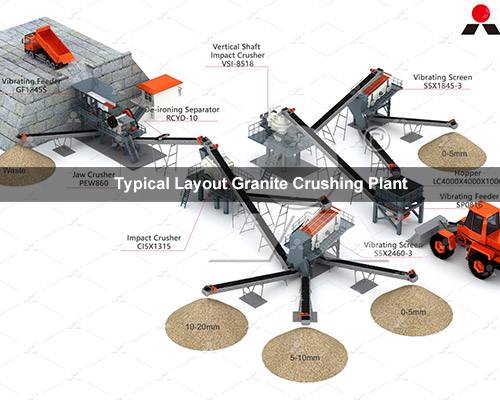

Typical Layout Granite Crushing Plant

Introduction to Granite Processing

Granite, as one of the hardest natural stones, requires specialized crushing equipment and plant layouts for efficient processing. Liming Heavy Industry, as a leading manufacturer of mining crusher and stone processing equipment, provides complete granite crushing plant solutions tailored to various production requirements.

Three-Stage Granite Crushing Plant Layout

1. Primary Crushing Stage

The granite crushing process typically begins with our rugged C6X Jaw Crusher, designed specifically for hard stone applications. With its optimized crushing chamber and durable components, the C6X effectively reduces large granite blocks (up to 1200mm) to smaller sizes (about 250-300mm).

2. Secondary Crushing Stage

The pre-crushed material then progresses to our high-performance HPT Hydraulic Cone Crusher. This stage further reduces granite particles to 40-70mm while maintaining excellent particle shape. The HPT series features:

- Advanced hydraulic control system

- Higher crushing efficiency

- Lower operational costs

3. Tertiary Crushing & Screening Stage

For applications requiring finer aggregates, our VSI6X Sand Making Machine processes materials to 0-5mm, 5-10mm, or 10-20mm specifications. The crushed granite is then precisely classified by our S5X Vibrating Screen, ensuring accurate particle size distribution.

Supporting Equipment in Granite Crushing Plants

A complete granite processing line from Liming Heavy Industry includes:

- ZSW Vibrating Feeder – for uniform material feeding

- B6X Belt Conveyor – reliable material transportation

- XSD Sand Washer – optional cleaning of final products

- Dust collection system – environmental protection

Mobile Granite Crushing Solutions

For flexible operations, Liming offers our NK Mobile Crushing Station series, combining jaw crusher, cone crusher, and screens on single chassis for quick deployment.

Why Choose Liming Heavy Industry?

As a professional manufacturer of mining crushing equipment, Liming provides:

- Engineered plant layouts customized to your granite characteristics

- Energy-efficient equipment with CE certification

- Comprehensive after-sales services

- 30+ years of experience in stone processing solutions

The optimal granite crushing plant layout combines proper equipment selection with efficient process flow design. Liming Heavy Industry’s complete solutions – from primary C6X Jaw Crusher to final sizing with S5X Screens – ensure maximum productivity in granite processing operations.