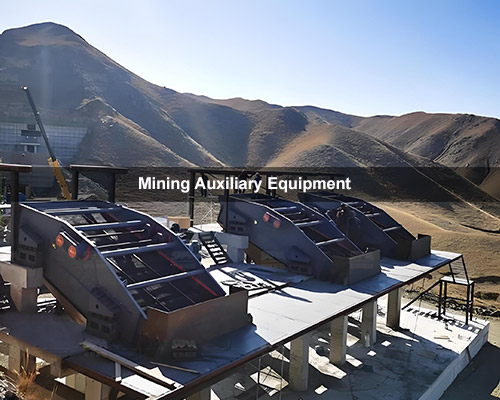

What is Mining Auxiliary Equipment?

In the world of aggregates and mineral processing, the spotlight often falls on the main crushers. However, to achieve optimal production capacity, the importance of the supporting machinery cannot be overstated. So, What is Mining Auxiliary Equipment? simply put, it refers to the essential machinery that supports the primary crushing and grinding processes, including Vibrating Feeders, Vibrating Screens, Belt Conveyors, and Sand Washers. At Liming Heavy Industry, we understand that a crushing line is only as strong as its weakest link.

As a leading manufacturer of stone crushers and mining auxiliary equipment, Liming Heavy Industry integrates advanced technology to ensure that every component of your plant works in perfect harmony, delivering high ROI and reliable performance.

1. Industry Pain Points: Why Your Crushing Plant Needs Upgrade

Many quarry operators and mining project managers face common challenges that eat into their profits. Without high-quality mining auxiliary equipment, you may encounter:

- Inconsistent Feeding: Uneven flow of material jams the primary jaw crusher, causing downtime.

- Poor Classification: Low screening efficiency leads to mixed aggregate sizes, reducing the market value of your final product.

- High Operational Costs: Frequent breakdowns of inferior belts or motors increase maintenance budgets.

- Environmental Issues: Excessive dust and dirty end-products due to lack of washing systems.

2. Liming Heavy Industry Solutions: Premium Auxiliary Equipment

To tackle these challenges, Liming Heavy Industry offers a comprehensive suite of auxiliary products designed for durability and precision.

Powerful Feeding: ZSW and GZD Series Vibrating Feeders

The Vibrating Feeder is the starting point of the production line. Our ZSW Series Vibrating Feeder and GZD Series Vibrating Feeder are engineered to feed blocky and granular materials uniformly into the primary crusher. They feature a double eccentric shaft vibration exciter, ensuring a strong vibrating force and stable operation.

Precise Screening: YK Series Vibrating Screens

Accurate separation is crucial. The YK Series Vibrating Screen is a multilayer, high-efficiency screen. It uses a cylinder-type eccentric shaft and partial block to adjust amplitude. Its long material flowing line and various screening specifications make it ideal for grading operations in quarries.

Clean Output: XSD Series Sand Washer

For high-quality manufactured sand, the XSD Series Sand Washer is essential. This wheel-bucket washing equipment removes dust and impurities from the sand, ensuring your product meets high-construction standards.

3. Technical Specifications Comparison

Choosing the right model depends on your capacity requirements. Below is a comparison of our popular auxiliary models:

| Equipment Type | Model | Max Feeding Size (mm) | Capacity (t/h) | Power (kW) |

|---|---|---|---|---|

| Vibrating Feeder | GZD-960×3800 | 500 | 80-150 | 11 |

| Vibrating Feeder | ZSW-490×110 | 650 | 280-500 | 22 |

| Vibrating Screen | 3YK1860 | 400 | 100-350 | 22 |

| Sand Washer | XSD3016 | 10 | 60-140 | 15 |

Note: Data is based on standard configurations. For custom specifications, please contact our engineering team.

4. Application Case Study: Granite Crushing in Southeast Asia

Project Background: A client in Southeast Asia needed a 300 t/h granite crushing line but struggled with high stone powder content and screen blockage.

The Solution: Liming Heavy Industry upgraded their line with:

- ZSW Series Vibrating Feeder for smooth primary feeding.

- 3YK2160 Vibrating Screen to separate aggregates into 0-5mm, 5-10mm, and 10-20mm.

- XSD3016 Sand Washer to clean the 0-5mm sand output.

Result: The efficiency of the crushing plant increased by 30%, and the cleanliness of the final sand product allowed the client to sell at a premium price.

5. Buying Guide: How to Select Mining Auxiliary Equipment

When purchasing from a screening equipment manufacturer, consider the following:

- Match the Capacity: Ensure the feeder and screen capacity matches your crushers (e.g., PE Jaw Crusher or HPT Cone Crusher).

- Material Properties: Wet or sticky materials may require specific screen meshes or washing systems.

- Site Layout: Consider the length and angle of Belt Conveyors (B6X Series) to fit your site terrain.

- After-Sales Support: Choose a supplier like Liming Heavy Industry that offers global installation and parts service.

6. FAQ: Common Questions About Auxiliary Equipment

Q1: How does a ZSW Vibrating Feeder differ from a GZD Series?

A: The ZSW Series is designed for heavy-duty operations with a grate bar design to pre-screen soil, while the GZD Series is typically used for lighter or secondary feeding applications.

Q2: Can the YK Vibrating Screen handle wet materials?

A: Yes, but the screen mesh type must be selected carefully to prevent clogging. Water spray pipes can also be installed on the YK Series for wet screening.

Q3: What maintenance does a Belt Conveyor require?

A: Regular inspection of the belt alignment, lubrication of rollers/idlers, and checking the tension of the belt are critical for the B6X Belt Conveyor.

Q4: Does Liming Heavy Industry provide spare parts?

A: Yes, we provide original spare parts for all our equipment, including screen meshes, springs, motors, and conveyor belts.

Q5: How do I get a quote for a complete crushing plant?

A: You can contact us directly through our website. Our engineers will design a customized flowchart based on your raw material and output requirements.

Investing in quality mining auxiliary equipment from Liming Heavy Industry delivers significant operational advantages and measurable ROI. Our comprehensive range of stone crushers, mine crushers, beneficiation equipment, and screening systems provides reliable solutions for the most challenging mining applications. Contact our technical specialists today to discuss how our equipment can optimize your mining operations and enhance your competitive position in the global market.