Machines Use for Basalt Stone Crushing

Basalt is a common extrusive volcanic rock with high hardness and abrasiveness, making it challenging to crush. Choosing the right crushing equipment is essential for efficient basalt processing in quarrying and mining operations. This article explores the most effective machines used for crushing basalt stone.

Jaw Crusher – Primary Crushing Solution

Jaw crusher are typically used as primary crusher in basalt crushing circuits. Their robust construction and powerful crushing action make them ideal for handling the hardness of basalt. Features include:

- High crushing ratio

- Simple structure

- Easy maintenance

- Reliable performance

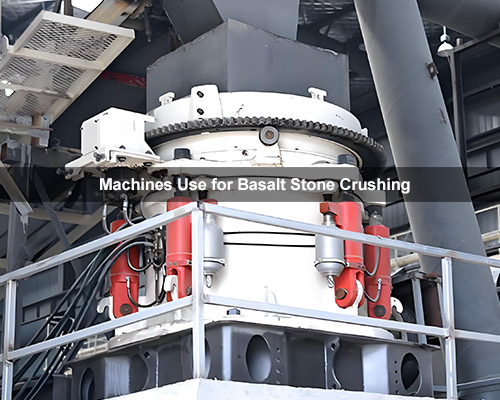

Cone Crusher – Secondary Crushing Excellence

For secondary crushing of basalt, cone crusher offer excellent particle shape and high production capacity. Benefits include:

- Superior particle shape

- Higher capacity than jaw crusher

- Hydraulic adjustment capabilities

- Lower operating costs

Impact Crusher – Alternative Crushing Option

VSI (Vertical Shaft Impact) crusher provide an alternative method for basalt crushing, especially when cubical-shaped particles are required:

- Produces highly cubical product

- Energy-efficient operation

- Suitable for tertiary crushing

- Excellent grain shape

Mobile Crushing Plants – Flexible Solutions

Mobile crushing plants combine crusher with screening equipment for on-site processing:

- Fully mobile operations

- Quick setup time

- Reduced transportation costs

- Customizable configurations

Selecting the right crushing equipment depends on your specific requirements for basalt processing, including required capacity, final product size, and mobility needs. Jaw crusher, cone crusher, impact crusher, and mobile crushing plants each offer unique advantages for different stages of basalt crushing operations.