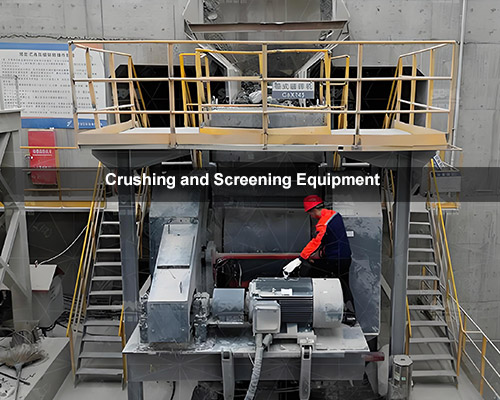

Crushing and Screening Equipment Manufacturers

As one of the top crushing and screening equipment manufacturers, Liming Heavy Industry provides high-performance machinery for processing various materials. This article covers material types, processing flows, equipment applications, capacities, innovations, and real-world case studies to help you optimize your operations.

Material Introduction

In the mining and construction industries, materials like granite, basalt, limestone, and iron ore require efficient processing. As crushing and screening equipment leaders, we design machinery to handle hard and abrasive materials, ensuring high productivity and minimal downtime. Common materials include aggregates for construction and minerals for industrial use.

Material Crushing and Screening Process

The typical process involves primary crushing, secondary crushing, and screening to achieve desired particle sizes. First, large rocks are reduced in jaw crushers, then further processed in impact or cone crushers. Screening equipment separates materials into different grades. This streamlined approach, supported by our crushing and screening equipment, enhances efficiency and output quality.

Application Range of Our Crushing Equipment

Liming Heavy Industry’s machinery is versatile, suitable for quarrying, mining, construction, and recycling. Our crushing and screening equipment handles diverse applications, such as producing aggregates for roads, processing ores for mineral extraction, and recycling construction waste. This wide applicability makes us trusted crushing and screening equipment manufacturers globally.

Crushing Equipment Capacity and Types

We offer a range of crushers with varying capacities to meet different production needs. Key models include:

- Jaw Crushers: Models like PE500×750 (capacity: 45-100 t/h), PE600×900 (capacity: 60-130 t/h), and PE750×1060 (capacity: 110-250 t/h) for primary crushing.

- Impact Crushers: PF1010 (capacity: 50-80 t/h), PF1210 (capacity: 70-130 t/h), and PF1315 (capacity: 120-250 t/h) for secondary crushing.

- Cone Crushers: HPT200 (capacity: 90-170 t/h), HPT300 (capacity: 120-250 t/h), and HPT500 (capacity: 250-550 t/h) for fine crushing.

- Screening Equipment: YK series vibrating screens, such as YK1235 and YK1545, for efficient material separation.

These options position us among the leading crushing and screening equipment manufacturers, catering to small to large-scale operations.

Technology and Innovation in Crushing Equipment

At Liming Heavy Industry, innovation drives our designs. We integrate features like hydraulic adjustment systems, automated control panels, and wear-resistant materials to extend equipment life and reduce maintenance. Our focus on R&D ensures that our crushing and screening equipment remains at the forefront of efficiency and sustainability.

Common Challenges and Solutions

Clients often face issues like high wear rates, low throughput, and uneven particle sizes. As experienced crushing and screening equipment leaders, we address these with:

- Wear Resistance: Using high-manganese steel in crusher parts to combat abrasion.

- Efficiency Optimization: Customizing crusher settings and screen configurations for specific materials.

- Downtime Reduction: Implementing easy-maintenance designs and remote monitoring capabilities.

These solutions help maximize productivity and minimize operational costs.

Case Study: Real-World Success with Data

In a limestone quarry project in Henan, China, a client used our PE750×1060 jaw crusher and PF1210 impact crusher in a closed-circuit system with a YK1545 vibrating screen. The setup processed 200 tons per hour of limestone, achieving a final product size of 0-20 mm with over 95% efficiency. This resulted in a 20% increase in production output and a 15% reduction in energy consumption compared to previous equipment, showcasing the reliability of our crushing and screening equipment.

Why Choose Liming Heavy Industry?

Selecting us as your crushing and screening equipment manufacturers means partnering with a company dedicated to quality, innovation, and customer support. Our advantages include:

- Proven track record with global clients.

- Comprehensive after-sales service and technical support.

- Customizable solutions tailored to your material and capacity needs.

- Commitment to sustainable and cost-effective operations.

For reliable crushing and screening equipment, trust Liming Heavy Industry to deliver results that drive your business forward.