Wiki

Last Updated :2023-08-01 Views:482

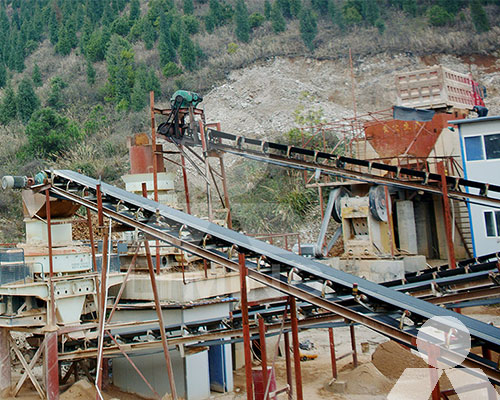

How to choose a complete set of crushing equipment?

Choosing a complete set of crushing equipment requires careful consideration of various factors to ensure that it meets your specific needs and maximizes productivity. Here is a step-by-step guide to help you make an informed decision:

- Define Your Requirements: Determine the type and size of materials you need to crush, the required production capacity, the final product size, and any specific features you may need (e.g., mobility, automation, etc.).

- Research Crushing Equipment Types: Familiarize yourself with different types of crushing equipment available in the market. Common types include jaw crushers, cone crushers, impact crushers, gyratory crushers, and more. Each type has its own strengths and suitable applications.

- Evaluate Your Budget: Set a budget for your crushing equipment. Consider not only the initial purchase cost but also maintenance, operation, and potential downtime expenses over the equipment’s lifespan.

- Consider Mobility: Depending on your project requirements, you might need either stationary or mobile crushing equipment. Mobile units offer greater flexibility but may come with higher costs.

- Quality and Reliability: Look for reputable manufacturers with a track record of producing high-quality, reliable crushing equipment. Check for warranties and after-sales support options.

- Energy Efficiency: Crushing equipment can consume significant energy. Consider selecting equipment with energy-efficient features to minimize operational costs.

- Safety Features: Ensure the equipment has necessary safety features, like emergency stops, guards, and warning systems to protect operators and maintenance personnel.

- Ease of Maintenance: Analyze the maintenance requirements of the equipment. Easy-to-maintain machines can reduce downtime and increase overall productivity.

- Compatibility and Integration: If you plan to integrate the crushing equipment with other machinery, make sure they are compatible and can work together seamlessly.

- Environmental Impact: Assess the environmental impact of the equipment, such as dust suppression systems and noise reduction measures, to comply with regulations and minimize negative effects.

- Consult with Experts: Seek advice from industry experts, equipment dealers, or manufacturers to get insights into the best options for your specific application.

- Visit Demos and Test Equipment: Whenever possible, visit equipment demonstrations or request to test the equipment before making a final decision. Hands-on experience will give you a better understanding of its performance and suitability for your needs.

- Check References and Reviews: Look for customer reviews and references from those who have used the equipment to gauge its real-world performance.

- Future Scalability: Consider if the equipment can handle potential future increases in production demands or if it can be easily upgraded or expanded.

- Compliance and Standards: Ensure that the equipment meets the necessary safety and regulatory standards applicable to your region or industry.

By following these steps, you can select a complete set of crushing equipment that aligns with your project requirements and provides long-term value for your investment. Remember that the right equipment can significantly impact your productivity and profitability.