News

Last Updated :2023-07-27

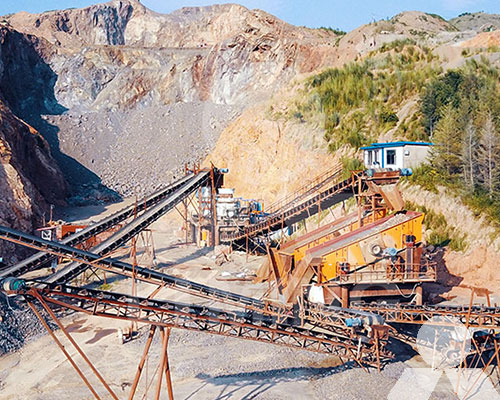

How to clean the crusher after long-term use?

Cleaning a crusher after long-term use is essential to maintain its efficiency, prevent contamination, and extend its lifespan. The cleaning process can vary depending on the type of crusher you have (e.g., jaw crusher, cone crusher, impact crusher) and the materials it processes. Here are some general steps to guide you through the cleaning process:

- Shut Down and Disconnect Power: Before starting any cleaning procedure, ensure that the crusher is completely shut down and disconnected from the power source. This is critical for safety reasons.

- Remove Residual Material: Clear out any remaining material in the crusher. Use appropriate tools to remove larger pieces, and avoid using metal tools that could damage the crusher components.

- Disassemble If Necessary: If possible and safe to do so, disassemble the crusher to access hard-to-reach areas and remove build-up or accumulated debris. Follow the manufacturer’s guidelines for disassembling the equipment.

- Clean Crusher Components: Depending on the crusher type, you may need to clean different components, such as:

- Crushing Chamber: Use a brush, compressed air, or vacuum to remove dust and debris from the crushing chamber.

- Jaws or Cones: If you have a jaw crusher or cone crusher, clean the crushing surfaces and ensure there is no residue left from the previously processed material.

- Hammers or Blow Bars: For impact crushers, check and clean the hammers or blow bars to maintain their effectiveness.

- Inspect and Replace Worn Parts: While cleaning, inspect all parts for signs of wear or damage. Replace any worn-out or damaged components to avoid performance issues and potential breakdowns in the future.

- Clean Screens or Grates: If your crusher has screens or grates, remove them and clean thoroughly to prevent blockages and maintain efficient material flow.

- Lubrication and Maintenance: After cleaning, apply lubrication to the appropriate parts according to the manufacturer’s recommendations. Regular maintenance is crucial to keep the crusher functioning optimally.

- Check Safety Features: Ensure that all safety features, such as emergency stop buttons or safety guards, are in good working condition.

- Reassemble and Test: Once you have completed the cleaning process and any necessary maintenance, reassemble the crusher following the manufacturer’s guidelines. After reassembly, perform a test run to verify that the crusher is working correctly and efficiently.

- Keep Records: Maintain a record of your cleaning and maintenance activities, including dates, tasks performed, and any issues found. This documentation will help you keep track of the crusher’s condition and plan future maintenance accordingly.

Always follow the specific cleaning and maintenance instructions provided by the crusher’s manufacturer. If you’re unsure about any aspect of the process or encounter complex issues, it’s best to consult a professional or the manufacturer’s support team for guidance.