Impact Mill Drawing for Mining in Nigeria

Impact milling is a method of grinding ore that uses the impact of falling particles to break down the material. Impact mill are commonly used in the mining industry to grind ore into a fine powder.

In Nigeria, impact mills are used in a variety of mining applications, including:

- Gold mining

- Iron ore mining

- Lead and zinc mining

- Coal mining

Impact mills are available in a variety of sizes and capacities. The size of the mill is determined by the amount of ore that needs to be ground. The capacity of the mill is determined by the amount of ore that can be ground in a given period of time.

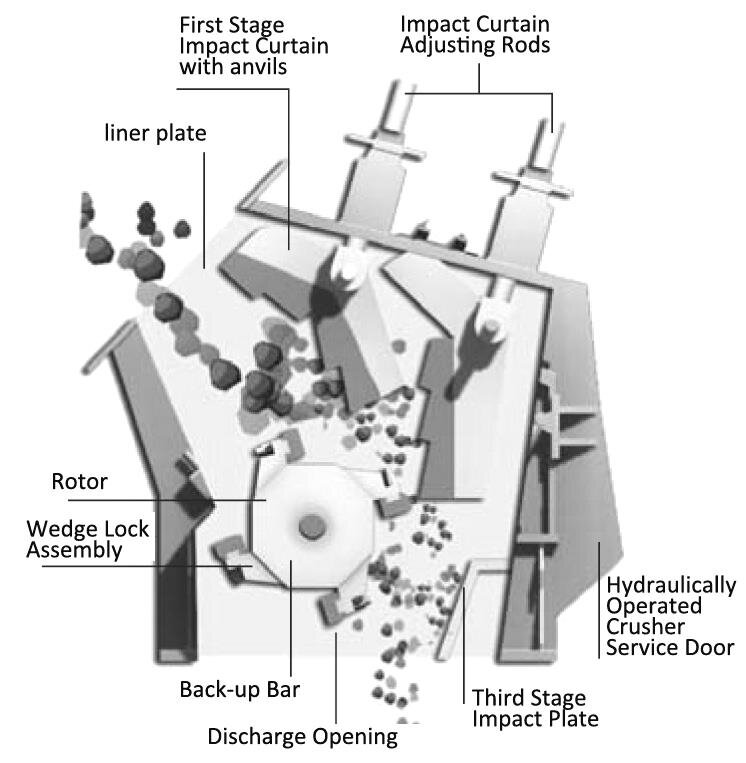

The basic components of an impact mill are as follows:

- Rotor: The rotor is a rotating shaft that contains the hammers. The hammers are responsible for impacting the ore particles.

- Casing: The casing is a cylindrical chamber that contains the rotor and the ore.

- Feeding system: The feeding system delivers the ore to the mill.

- Discharge system: The discharge system conveys the ground ore from the mill.

The operation of an impact mill is as follows:

- The ore is fed into the mill through the feeding system.

- The rotor rotates and the hammers impact the ore particles.

- The impact of the hammers breaks down the ore particles into a fine powder.

- The ground ore is discharged from the mill through the discharge system.

Impact mills are a versatile and efficient method of grinding ore. They are widely used in the mining industry to grind ore into a fine powder.

Here are some of the advantages of using impact mills in mining:

- They are efficient at grinding ore into a fine powder.

- They are relatively easy to operate and maintain.

- They are available in a variety of sizes and capacities.

Here are some of the disadvantages of using impact mills in mining:

- They can be noisy.

- They can produce a lot of dust.

- They can be expensive to purchase and install.