YKN Series Vibrating Screen

YKN Series Vibrating Screen, developed by Liming Heavy Industry, represents a breakthrough in the field of screening technology. With its innovative design and advanced features, this vibrating screen offers a new dimension of efficiency and productivity in material separation processes. By providing precise and reliable screening, the YKN Series Vibrating Screen has gained significant recognition in various industries.This machine can change the exciting force by adjusting number of secondary eccentric block, thus the different requirements about amplitude can be met.

Input Size: 0-400mm

Capacity: 70-1200TPH

Material: Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore, coal and so on.

Key Features

YKN Series Vibrating Screen boasts several key features that set it apart from conventional vibrating screens:

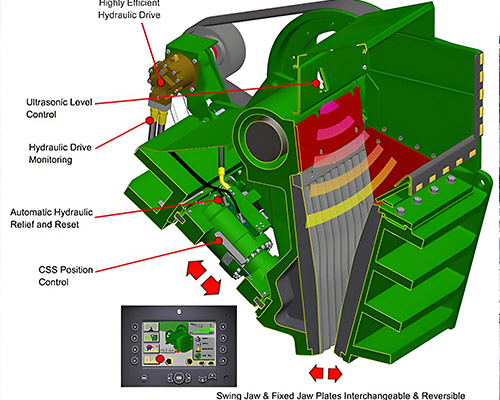

- a) Eccentric Block Exciter: The screen utilizes an eccentric block exciter that generates strong centrifugal force, ensuring efficient and consistent screening performance.

- b) High Vibrating Frequency: With a high-frequency vibrating system, the YKN Series Vibrating Screen offers improved screening efficiency and capacity, effectively separating particles of different sizes.

- c) Adjustable Amplitude: The screen allows users to adjust the amplitude according to specific requirements, enabling precise control over the screening process.

- d) Modular Design: The modular design of the YKN Series Vibrating Screen enhances its flexibility and ease of maintenance, allowing for quick and convenient screen panel replacement.

- e) Advanced Materials and Manufacturing: The screen is constructed with high-quality materials and advanced manufacturing techniques, ensuring durability and prolonged operational life.

Working Principle

YKN Series Vibrating Screen operates based on the principle of vibration, which is generated by the eccentric block exciter. The exciter imparts a circular motion to the screen, causing the material to move across the surface in a spiraling pattern. As the material passes through the screen, particles of different sizes are separated, resulting in efficient classification and sorting.

Significant Applications

YKN Series Vibrating Screen finds applications in a wide range of industries, including but not limited to:

- a) Mining and Quarrying: The screen efficiently separates minerals and aggregates, enabling the extraction of valuable materials while minimizing waste.

- b) Construction: It is used for screening construction materials, such as sand, gravel, and crushed stones, ensuring the quality and consistency of building materials.

- c) Recycling: The YKN Series Vibrating Screen aids in the sorting and separation of recyclable materials, contributing to sustainable waste management practices.

- d) Chemical and Pharmaceutical: It assists in the classification and separation of chemicals and pharmaceutical products, ensuring product quality and purity.

- e) Metallurgy: The screen is utilized in metallurgical processes to classify and separate various metal ores, optimizing production efficiency.

Future Developments

YKN Series Vibrating Screen serves as a stepping stone for further advancements in screening technology. Future developments may focus on: a) Integration of Smart Technologies: Incorporating intelligent features such as automation, remote monitoring, and real-time diagnostics to enhance operational efficiency and reduce maintenance costs.

b) Enhanced Customization: Offering a wider range of screen configurations and sizes to cater to specific industry needs and requirements.

c) Improved Energy Efficiency: Developing energy-efficient vibrating screens to minimize power consumption and reduce environmental impact.

d) Enhanced Durability: Exploring advanced materials and manufacturing techniques to enhance the screen’s durability and prolong its operational life.

Product Parameters