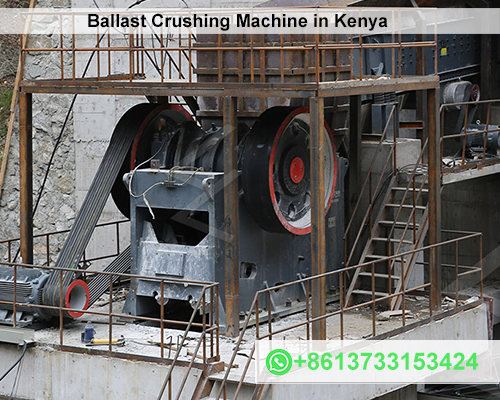

Kenya Jaw Crusher Plant Produce Ballast and Sand

In Kenya, the construction and infrastructure industries are experiencing rapid growth, particularly with the expansion of roads, railways, and buildings. Ballast, which is a critical component in road construction and railway track laying, is in high demand. Ballast refers to crushed stones or gravel used to support the foundation of roads, railway lines, and other structures. Due to its importance, there is a need for efficient, reliable, and simple ballast crushing machines to meet this growing demand.

In this article, we explore the basics of ballast crushing machines in Kenya, focusing on their simplicity, efficiency, and how they contribute to the construction industry.

What is Ballast?

Ballast is made up of coarse aggregates such as gravel, crushed stone, or sand. It serves as a key material for roadbeds and railway track foundations. Its main function is to distribute the weight of trains and vehicles evenly, providing stability, drainage, and support.

In Kenya, the need for high-quality ballast has increased with ongoing infrastructure projects. The natural resources in various parts of the country, particularly in areas like Machakos, Kiambu, and parts of Nyanza, provide abundant materials suitable for ballast production.

Simple Ballast Crushing Machines

Ballast crushing machines are designed to crush larger rocks into smaller, usable aggregates. The process involves several stages: primary crushing, secondary crushing, and sometimes tertiary crushing, depending on the size of the output required. However, many Kenyan companies use simple ballast crushing machines due to their cost-effectiveness, ease of operation, and suitability for small-scale operations.

Types of Simple Ballast Crushing Machines

The most common types of simple ballast crushing machines in Kenya include:

- Jaw Crusher:

These are the most widely used primary crusher in Kenya. Jaw crusher consist of a pair of jaws that open and close, compressing the stone between them. As the stones move through the jaws, they break into smaller pieces. Jaw crusher is known for their simplicity and reliability. They are especially ideal for hard materials like granite, which are common in Kenya’s ballast. - Cone Crusher:

After the primary crushing stage, a cone crusher is often used for secondary crushing. Cone crusher have a conical shape that helps break rocks into finer aggregates. They are efficient and can handle materials of varying hardness. While more complex than jaw crusher, they are still simple to operate and maintain. - Impact Crusher:

These crusher use the force of impact to break down materials. The rotor of the machine rotates at high speed, striking the rocks and breaking them apart. Impact crusher is often used for producing fine ballast that can be used in road construction or other smaller projects. - Hammer Crusher:

A hammer crusher operates on a similar principle as an impact crusher but uses a series of rotating hammers to break down the stone. This type of machine is effective for producing finer aggregates, making it an essential tool in producing quality ballast. - Vibrating Screens:

After the crushing process, a vibrating screen is used to sift through the crushed material, separating it into different sizes. This ensures that only the desired size of aggregates is used in construction, with the larger particles being sent back to the crusher for further processing.

Why Simple Ballast Crushing Machines Are Popular in Kenya

- Affordability and Accessibility: Simple ballast crushing machines are relatively inexpensive compared to larger, more complex machinery. For small and medium-scale enterprises in Kenya, these machines provide a cost-effective solution for ballast production. The affordability also means that construction companies can invest in their own equipment, reducing the need for costly outsourcing.

- Ease of Operation: Simple crushing machines are designed for easy operation. Even workers with minimal technical skills can learn to operate the equipment with basic training. This ease of use is a significant advantage in rural areas where skilled labor may be scarce.

- Low Maintenance Costs: These machines generally have fewer moving parts than more complex machinery, leading to lower maintenance and repair costs. With proper care and periodic maintenance, a simple ballast crushing machine can run for years, making it a durable investment.

- Portability: Many simple ballast crusher is portable, meaning they can be moved from one site to another. This is particularly beneficial in Kenya, where construction projects are spread across the country. The ability to transport machinery to different locations allows for flexibility and increased productivity.

- High Productivity: Despite their simplicity, these machines are designed to crush large quantities of ballast in a short amount of time. This high productivity helps keep up with the demand for ballast in various construction projects.

How Simple Ballast Crushing Machines Contribute to the Economy

The growing demand for ballast in Kenya has a direct impact on local economies, especially in rural areas. Simple ballast crushing machines support small-scale businesses, provide job opportunities, and contribute to the local economy by ensuring a steady supply of crushed aggregates.

Furthermore, local production of ballast reduces the need for importing materials, thus cutting costs and promoting self-sufficiency in the construction sector. By improving efficiency in ballast production, simple crushing machines also help to reduce the cost of construction, which has positive implications for infrastructure development.

Challenges in Ballast Crushing Operations

Despite their advantages, there are some challenges associated with ballast crushing operations in Kenya:

- Environmental Concerns: The extraction and crushing of ballast can lead to environmental degradation, including soil erosion, dust pollution, and depletion of natural resources. It is essential for operators to adhere to environmental guidelines and implement sustainable practices.

- Competition and Market Saturation: As more businesses enter the ballast production market, competition has increased. This can drive down prices and affect the profitability of small-scale operators.

- Logistical Challenges: Transporting large quantities of crushed ballast to construction sites can be expensive, especially in areas with poor road infrastructure.

Conclusion

Simple ballast crushing machines play a critical role in meeting the growing demand for construction materials in Kenya. They are affordable, easy to operate, and provide a sustainable solution for small-scale ballast production. While they come with some challenges, their impact on Kenya’s construction industry cannot be understated. As infrastructure projects continue to expand, the role of efficient ballast crushing machines will remain essential to the country’s development.