Track-type Mobile Crusher

Introduction:

Track-type mobile crushers are cutting-edge crushing equipment designed for on-site mobility and adaptability. Equipped with tracks, they can easily navigate diverse terrains, making them highly versatile in different working environments. This feature sets them apart from traditional stationary crushers and enables efficient and flexible crushing operations.

Output size : 480-940MM

Production capacity : 90-650T/H

Applications: Mining, metallurgy, construction, highway, railway, and water conservancy, etc.

Classification:

Track-type mobile crushers can be classified into various types based on their specific functionalities and design features:

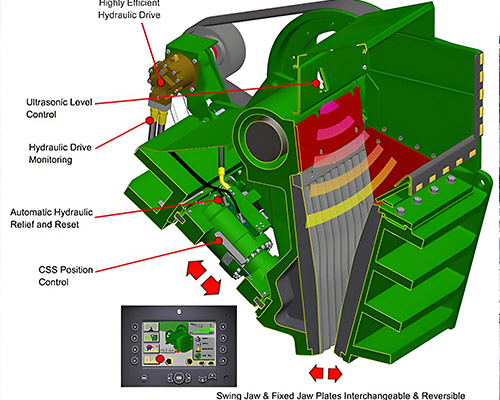

Jaw Crushers:

Jaw crushers are primarily used for primary crushing operations. They consist of a fixed jaw and a movable jaw, between which the material is crushed. Jaw crushers are suitable for processing various materials, including hard rocks, ores, and recycled concrete.

Impact Crushers:

Impact crushers are designed to crush materials using impact forces. They utilize a high-speed rotor and hammers to break down the material. Impact crushers are well-suited for both primary and secondary crushing applications and are commonly used in quarrying, mining, and construction industries.

Cone Crushers:

Cone crushers are used for secondary and tertiary crushing. They operate by compressing the material between an eccentrically rotating mantle and a concave. Cone crushers are widely employed in the mining and aggregate industries, offering high production efficiency and excellent particle shape.

Configuration:

Track-type mobile crushers are equipped with several essential components to ensure efficient operation:

1. Mobile Chassis:

The mobile chassis provides a stable platform for the crusher, incorporating tracks for mobility. It allows the crusher to move easily across different terrains, enabling on-site crushing.

2. Crusher Unit:

The crusher unit comprises the primary crusher (jaw, impact, or cone), responsible for crushing the material to the desired size. It incorporates a powerful motor, crushing chamber, and discharge mechanism.

3. Feeding and Conveying System:

The feeding and conveying system ensures a continuous supply of material to the crusher unit. It typically includes a vibrating feeder, conveyor belts, and a hopper for efficient material handling.

Applications:

Track-type mobile crushers find extensive applications in various industries, including:

1. Construction and Demolition Waste Recycling:

Track-type mobile crushers enable efficient on-site processing of construction and demolition waste. They can crush and separate different materials, such as concrete, bricks, and asphalt, facilitating recycling and reducing transportation costs.

2. Quarrying and Mining:

In quarrying and mining operations, track-type mobile crushers are used to extract and process minerals and aggregates. They can handle various types of rocks and ores, providing high productivity and mobility for efficient crushing operations.

3. Road Construction:

Track-type mobile crushers play a vital role in road construction projects. They can crush and process materials directly at the construction site, eliminating the need for transportation and reducing project timelines. These crushers are particularly useful for crushing gravel, asphalt, and other road materials.

Advantages:

Track-type mobile crushers offer numerous advantages over traditional stationary crushers, including:

1. High Mobility:

Track-type mobile crushers can easily traverse different terrains, providing enhanced mobility and flexibility for on-site crushing operations.

2. On-Site Crushing:

These crushers enable on-site processing, eliminating the need for material transportation and reducing costs associated with logistics.

3. Versatility:

With a variety of crusher types available.

Product Parameters