Common Types Of Rock Crushing Equipment

There is several common types of rock crushing equipment, each with its own advantages and disadvantages. The best type of crusher for a particular application will depend on the size and type of rock being crushed, the desired size of the finished product, and the production capacity required.

Here is some of the most common types of rock crushing equipment:

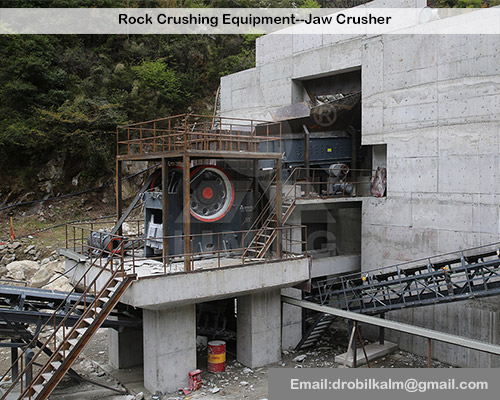

Jaw crusher: Jaw crusher is the most widely used type of crusher. They use a compressive force to break rock between two opposing jaws. Jaw crusher is good for breaking hard and abrasive rock, but they is not as effective for producing cubical-shaped product.

Gyratory crusher: Gyratory crusher is similar to jaw crusher, but they use a cone-shaped crushing chamber instead of two flat jaws. Gyratory crusher can produce a more cubical-shaped product than jaw crusher, and they is also more efficient.

Cone crusher: Cone crusher use a rotating cone to break rock against a stationary cone. Cone crusher is very efficient and can produce a very cubical-shaped product. They is a good choice for secondary and tertiary crushing applications.

Impact crusher: Impact crusher use high-speed impellers to break rock by impact. Impact crusher is good for breaking friable rock, but they is not as effective for producing cubical-shaped product.

Hammer Mills: Hammer mills use hammers to break rock by impact. Hammer mills is similar to impact crusher, but they is typically used for producing very fine crushed rock.

Other factors to consider when selecting rock crushing equipment include the cost of the equipment, the cost of operation and maintenance, and the environmental impact of the operation.