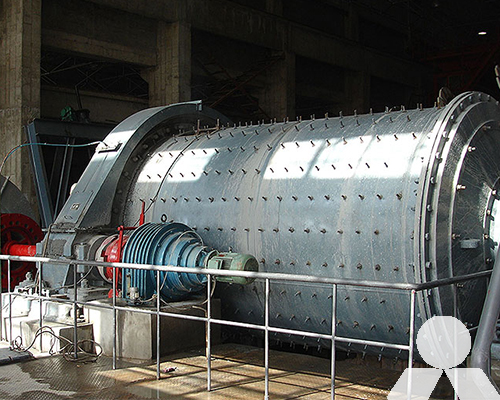

High Performance Ball Mill for Gypsum Powder Making

Gypsum powder is a versatile material with a wide range of applications. It is used in construction, building materials, industrial molds and models, chemical industry, agriculture, food processing, and pharmaceuticals. The production of gypsum powder requires a high-performance ball mill.

A ball mill is a type of grinding mill that uses rotating balls to grind materials into a fine powder. The balls are typically made of steel or ceramic and are contained within a cylindrical chamber. The chamber is rotated at a high speed, causing the balls to collide with each other and with the material being ground. This results in the material being broken down into smaller and smaller particles.

The performance of a ball mill is determined by a number of factors, including the size and shape of the chamber, the speed of rotation, the type of balls used, and the loading of the mill. A high-performance ball mill will have a large chamber with a high speed of rotation. The balls should be made of a durable material that can withstand the high-impact forces involved in the grinding process. The loading of the mill should be optimized to ensure that the balls are able to effectively grind the material.

There are a number of advantages to using a high-performance ball mill for gypsum powder making. First, it can produce a finer powder than a lower-performance mill. This is important for applications where a high degree of uniformity is required, such as in the construction industry. Second, a high-performance mill can produce gypsum powder at a faster rate. This can save time and money, especially for large-scale production. Finally, a high-performance mill is more energy efficient than a lower-performance mill. This can reduce operating costs and environmental impact.

There are a number of different types of high-performance ball mills available for gypsum powder making. Some of the most common types include:

- Vertical ball mills: These mills are typically used for large-scale production. They have a vertical cylindrical chamber that is rotated at a high speed.

- Horizontal ball mills: These mills are typically used for smaller-scale production. They have a horizontal cylindrical chamber that is rotated at a lower speed.

- Semi-wet ball mills: These mills use a mixture of water and gypsum to grind the material. This helps to reduce dust and improve the efficiency of the grinding process.

The type of ball mill that is best for a particular application will depend on a number of factors, including the desired particle size, production rate, and budget.

Benefits of Using a High-Performance Ball Mill for Gypsum Powder Making

The use of a high-performance ball mill for gypsum powder making offers a number of benefits, including:

- Finer powder: A high-performance ball mill can produce a finer powder than a lower-performance mill. This is important for applications where a high degree of uniformity is required, such as in the construction industry.

- Faster production: A high-performance mill can produce gypsum powder at a faster rate. This can save time and money, especially for large-scale production.

- Energy efficiency: A high-performance mill is more energy efficient than a lower-performance mill. This can reduce operating costs and environmental impact.

A high-performance ball mill is a valuable asset for any gypsum powder production facility. It can produce a finer, faster, and more energy-efficient powder than a lower-performance mill.