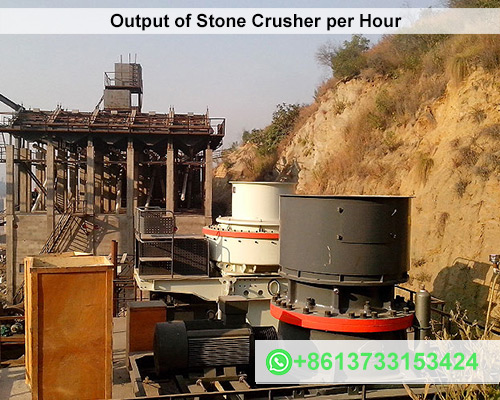

The Output of Stone Crusher per Hour

Stone crusher is essential machines used in the mining and construction industries for breaking down large rocks into smaller, usable materials. The output of a stone crusher per hour can vary significantly based on several factors, including the type of crusher, the size of the material being processed, and the required output size. Understanding these variables is crucial for optimizing the production process and meeting project demands.

1. Types of Stone Crusher

Several types of stone crusher is used in different applications, each with unique characteristics that influence the hourly output. The most common types include:

- Jaw Crusher: These are primarily used for the initial crushing stage and are capable of handling large rock sizes. They generally offer a lower output per hour compared to other types.

- Cone Crusher: Used for secondary or tertiary crushing, cone crusher offer a higher output due to their ability to crush materials into finer particles.

- Impact Crusher: Known for producing high-quality, finely crushed stone, these are suitable for operations requiring specific material shapes and gradation.

- Gyratory Crusher: Larger and more powerful than jaw crusher, these are often used in primary crushing applications with high-volume output requirements.

2. Factors Affecting Output per Hour

Several factors impact the output of a stone crusher. Below are the key variables:

a. Material Hardness and Density

The hardness and density of the stone being crushed play a critical role in determining crusher performance. Harder materials, such as granite or basalt, are more difficult to crush and require more power, which can reduce output. Softer materials, like limestone, can be processed more quickly, increasing output.

b. Feed Size

The size of the material fed into the crusher directly influences the machine’s efficiency. Larger feed sizes can slow down the crushing process as more energy is required to break the stone. Jaw crusher, for instance, are more effective with larger rock sizes, while cone crusher handle smaller, more uniform materials efficiently.

c. Discharge Size

The output size desired after crushing also affects the machine’s hourly output. A smaller discharge size will slow down the crusher since more time is required to crush the stone into finer particles. Conversely, larger output sizes allow the machine to process more material quickly, increasing output per hour.

d. Machine Power and Capacity

Each stone crusher comes with its own power and throughput capacity. The rated capacity, typically given in tons per hour (tph), depends on the type of crusher and its design. For example, a jaw crusher might produce between 20-100 tons per hour, whereas larger gyratory or cone crusher can achieve outputs of 200-500 tons per hour or more.

e. Operating Efficiency

Factors such as maintenance, operator skill, and the overall condition of the equipment also affect the machine’s performance. Well-maintained machines operating at peak efficiency produce higher outputs per hour compared to equipment experiencing mechanical issues or being improperly operated.

3. Calculating Output per Hour

To calculate the output per hour of a stone crusher, the following formula can be applied:Hourly Output (tons/hour)=Machine Capacity (tons/hour)×Efficiency Factor\text{Hourly Output (tons/hour)} = \text{Machine Capacity (tons/hour)} \times \text{Efficiency Factor}Hourly Output (tons/hour)=Machine Capacity (tons/hour)×Efficiency Factor

Where:

- Machine Capacity refers to the rated output of the crusher.

- Efficiency Factor accounts for variables such as operator proficiency, material type, and feed consistency. Typically, this factor ranges from 0.7 to 0.9.

For example, a cone crusher with a rated capacity of 300 tons per hour and operating at 85% efficiency would produce:300 tons/hour×0.85=255 tons/hour300 \, \text{tons/hour} \times 0.85 = 255 \, \text{tons/hour}300tons/hour×0.85=255tons/hour

4. Typical Output Ranges by Crusher Type

- Jaw Crusher: 20–100 tons per hour

- Cone Crusher: 100–500 tons per hour

- Impact Crusher: 50–300 tons per hour

- Gyratory Crusher: 200–800 tons per hour

5. Optimizing Output

To maximize the output of a stone crusher per hour, several best practices can be implemented:

- Regular Maintenance: Routine maintenance ensures the machine operates at peak performance and minimizes downtime.

- Operator Training: Skilled operators can adjust feed rates and settings to ensure optimal throughput.

- Matching Crusher Type to Material: Using the right crusher for the material being processed can significantly boost output. For instance, softer stones work well with jaw or impact crusher, while harder stones are better suited to cone or gyratory crusher.

- Feed Consistency: Ensuring a consistent flow of material into the crusher helps maintain steady output, avoiding peaks and troughs in production.

Conclusion

The output of a stone crusher per hour depends on several interrelated factors, including the type of crusher, material characteristics, feed size, and operational efficiency. While the rated capacity of a crusher provides a baseline, real-world conditions can influence the actual output. By understanding these factors and implementing best practices, it is possible to maximize productivity and achieve efficient, cost-effective crushing operations.