News

Last Updated :2023-07-22

Why are rod mill not suitable for producing sand?

Rod mills are not typically used for producing sand because of their design and operational characteristics. Here are some reasons why rod mills are not suitable for producing sand:

- Particle size control: Rod mills are designed to operate with relatively coarse feed materials and to produce a product with a relatively large particle size. In contrast, sand requires a much finer particle size distribution. The high speed of rotation and the action of the rods in the mill tend to break down the larger particles into smaller pieces, but they may not achieve the fine particle size required for sand.

- Shape and grading: Sand used in various applications like construction, concrete, and asphalt requires a specific shape and grading to ensure proper compaction and performance. Rod mills tend to produce more elongated and irregularly shaped particles, which may not meet the required specifications for sand.

- Abrasion and wear: Rod mills use rods as grinding media, which can lead to a high level of abrasion and wear of the equipment. The presence of abrasive materials in the feed, such as certain types of rocks or minerals, can accelerate the wear of the rods and the interior of the mill, reducing its efficiency and increasing maintenance costs.

- Energy consumption: Rod mills generally consume more energy compared to other types of mills, especially when trying to achieve fine grinding for sand production. This can result in higher operating costs and make the production of sand less economical.

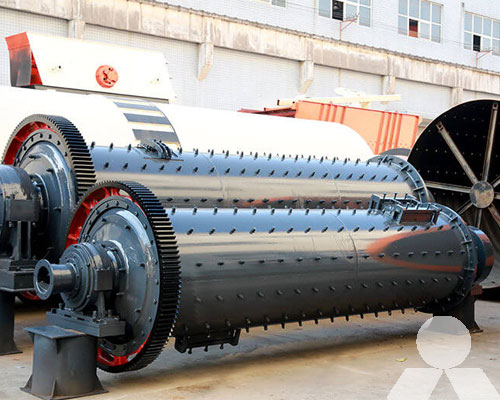

- Alternative equipment: There are more suitable equipment options available for producing sand, such as ball mills, vertical shaft impactors (VSI), and horizontal impact crushers. These machines are specifically designed for finer grinding and shaping of particles, making them more appropriate for sand production.

Overall, while rod mills are useful for certain types of grinding tasks, they are not the ideal choice for producing sand due to their limitations in particle size control, shape and grading, high wear rates, and higher energy consumption compared to other specialized equipment designed for sand production.