Pebble crushing plant

Pebble crushing plants have gained significant attention in the construction and mining industries due to their ability to produce high-quality aggregates.The demand for construction aggregates continues to rise as infrastructure development and urbanization projects expand globally. Pebble crushing plants offer a viable solution to meet this increasing demand. These plants specialize in processing pebbles, a type of rock commonly found in riverbeds and coastal areas, into smaller, consistent-sized aggregates that are used in various construction applications.

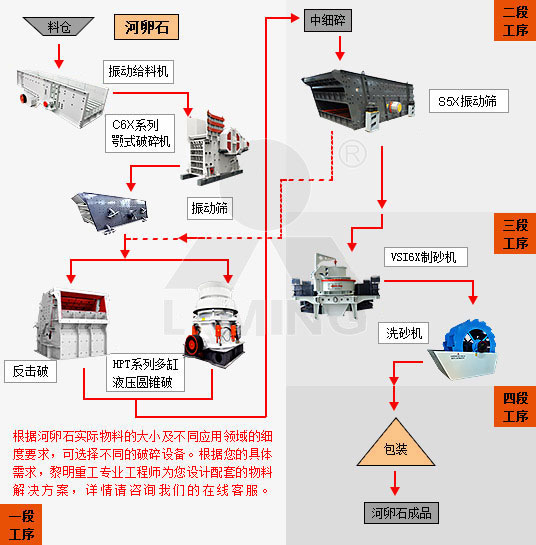

Pebble Crushing Technology

1. Crushers:

The primary crusher plays a vital role in the pebble crushing process. Depending on the specific requirements, jaw crushers, cone crushers, or impact crushers can be chosen. The selection is based on factors such as the hardness and size of the pebbles, desired aggregate specifications, and production capacity.

2. Screens:

Screens are used to separate the crushed pebbles into different sizes. Vibrating screens with various mesh sizes are commonly employed for this purpose. The selection of screens depends on the required particle size distribution and capacity of the plant.

3. Conveyors:

Conveyors are responsible for transporting the crushed pebbles between different stages of the crushing process. They ensure a smooth and continuous flow of material. Proper conveyor selection includes considering factors such as material handling capacity, distance, and elevation changes.

4. Storage Facilities:

Storage facilities are necessary for storing the crushed pebbles before they are transported for further processing or sale. Silos, bins, or stockpiles can be used as storage solutions, depending on the plant’s requirements and the volume of aggregates produced.