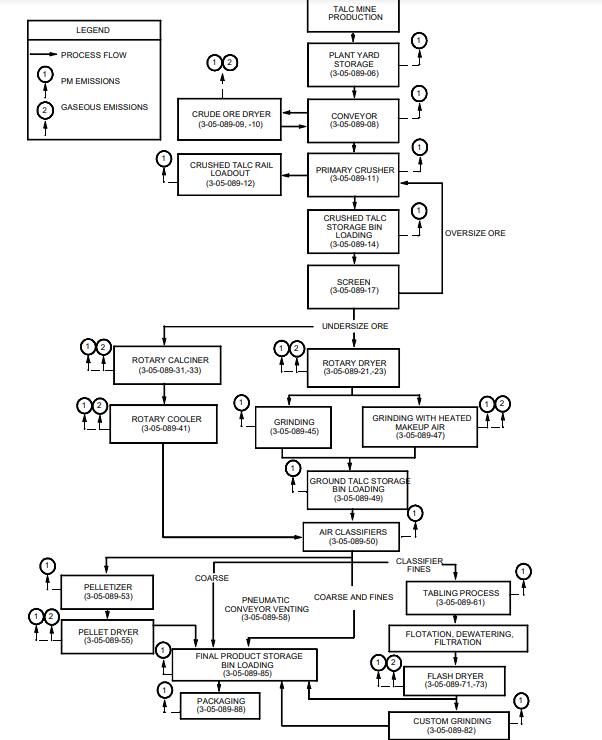

Process Flow Diagram for Talc Processing

Talc, which is a soft, hydrous magnesium silicate (3Mg0 4Si0 H 0), is used in a wide range of industries including the manufacture of ceramics, paints, paper, and asphalt roofing. The end-uses for talc are determined by variables such as chemical and mineralogical composition, particle size and shape, specific gravity, hardness, and color.

Talc ore generally is hauled to the plant by truck from a nearby mine. The ore is crushed, typically in a jaw crusher, and screened. The coarse (oversize) material then is returned to the crusher. Rotary dryers may be used to dry the material. Secondary grinding is achieved with pebble mills or roller mills, producing a product that is 44 to 149 micrometers ( m) (325 to 100 mesh) in size. Some roller mills are designed to use heated air to dry the material as it is being ground. Hammer mills or steam- or compressed airpowered jet mills may be used to produce additional final products. Air classifiers (separators),generally in closed circuit with the mills, separate the material into coarse, coarse-plus-fine, and fine fractions. The coarse and coarse-plus-fine fractions then are stored as products. The fines may be concentrated using a shaking table (tabling process) to separate product containing small quantities of nickel, iron, cobalt, or other minerals and then may undergo a one-step flotation process. The resultant talc slurry is dewatered and filtered prior to passing through a flash dryer.

In the pelletizing step, processed talc is mixed with water to form a paste and then is extruded as pellets. Generally, a separate product will be used to produce the calcined talc. Prior to calcining, the mined ore passes through a crusher and is ground to a specified screen size.

After calcining in a rotary kiln, the material passes through a rotary cooler. The cooled calcine (0 percent free water) is then either stored for shipment or further processed. Calcined talc may be mixed with dried talc from other product lines and passed through a roller mill prior to bulk shipping.Particulate matter is emitted from drilling, blasting, crushing, screening,grinding, drying, calcining, classifying, materials handling and transfer operations, packaging, and storage. Although pelletizing is a wet process, PM may be emitted from the transfer and feeding of processed talc to the pelletizer. Depending on the purity of the talc ore body, PM emissions may include trace amounts of several inorganic compounds that are listed hazardous air pollutants (HAP),including arsenic, cadmium, chromium, cobalt, manganese, nickel, and phosphorus.

The emissions from dryers and calciners include products of combustion, such as carbon monoxide, carbon dioxide, nitrogen oxides, and sulfur oxides, in addition to filterable and condensible PM. Products of combustion and VOC may also be emitted from roller mills that use heated air and from the furnaces that provide the heated air to the mill. Emissions from talc dryers and calciners are typically controlled with fabric filters. Fabric filters also are used at some facilities to control emissions from mechanical processes such as crushing and grinding.