Wiki

Last Updated :2023-08-01 Views:580

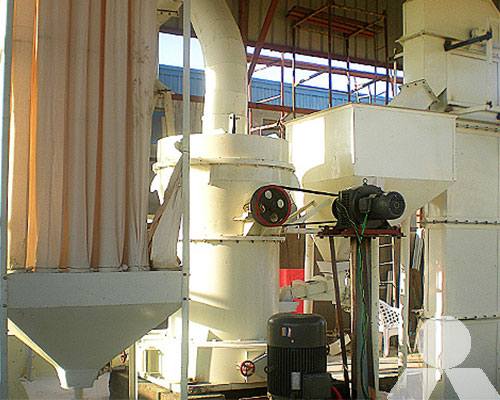

What’s the difference between Raymond Mill and Ball Mill?

Raymond Mill and Ball Mill are both commonly used milling equipment in various industries, but they have different working principles, applications, and features. Here’s a brief comparison between the two:

- Working Principle:

- Raymond Mill: Raymond Mill is also known as Raymond Roller Mill. It works by grinding materials between the rollers and the grinding ring. The rollers rotate outward, pressing the material against the grinding ring. The crushed material is carried upwards with the airflow and then separated through a classifier for the desired particle size.

- Ball Mill: Ball Mill is a horizontal rotating device with a cylindrical drum or shell. The grinding media (usually steel balls) in the cylinder are lifted to a certain height, and then they fall back down, impacting and grinding the materials fed into the mill.

- Application:

- Raymond Mill: Raymond Mill is mainly used for grinding non-flammable and non-explosive materials with Mohs hardness less than 9.3 and humidity below 6%. It is widely used in industries like metallurgy, construction, chemical engineering, mining, etc., for processing various materials like limestone, calcite, barite, dolomite, marble, talcum, gypsum, and so on.

- Ball Mill: Ball Mill is used for grinding materials mainly in the mineral processing industry, cement production, chemical industry, and other industries. It is used for both dry and wet grinding of various ores and other grindable materials.

- Product Particle Size:

- Raymond Mill: The finished product size is typically between 80-325 mesh (0.044mm – 0.173mm). Some materials can be ground to as fine as 600 mesh (0.025mm).

- Ball Mill: The finished product size varies from 200 mesh (0.074mm) to 325 mesh (0.044mm) or even finer.

- Energy Consumption:

- Raymond Mill: Generally, the energy consumption of Raymond Mill is higher than that of Ball Mill for the same grinding fineness.

- Ball Mill: Ball Mill has a lower energy consumption when compared to Raymond Mill of similar capacity.

- Maintenance and Operation:

- Raymond Mill: The maintenance and operation of Raymond Mill are relatively simple, and it requires regular lubrication of bearings and frequent replacement of wearing parts like grinding ring and roller.

- Ball Mill: Ball Mill requires regular inspection, lubrication, and replacement of worn-out liners and grinding media.

In summary, Raymond Mill is more suitable for processing non-flammable and non-explosive materials with medium hardness, while Ball Mill is more suitable for grinding various ores and other materials with higher hardness. The choice between the two depends on the specific material, required particle size, and production capacity.