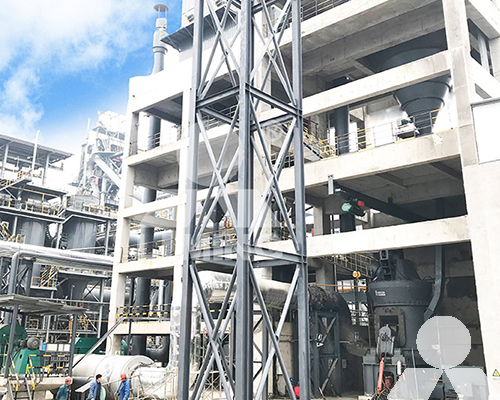

Limestone Powder Grinding Mills in Iraq

Limestone is a common mineral found in many parts of the world, including Iraq. It is used in a variety of applications, including construction, agriculture, and manufacturing. Limestone powder is a finely ground form of limestone that is used in a variety of applications, including cement, paint, and paper.

There are a number of different types of limestone powder grinding mills available, each with its own advantages and disadvantages. The most common type of limestone powder grinding mill in Iraq is the ball mill. Ball mills are relatively inexpensive and easy to maintain, but they can be inefficient for grinding coarse materials.

Another type of limestone powder grinding mill that is becoming increasingly popular in Iraq is the vertical roller mill. Vertical roller mills are more efficient than ball mills for grinding coarse materials, and they also produce a finer product. However, vertical roller mills are more expensive than ball mills and require more maintenance.

The type of limestone powder grinding mill that is best for a particular application will depend on a number of factors, including the size of the operation, the type of limestone to be ground, and the desired product specifications.

Ball Mills

Ball mills are the most common type of limestone powder grinding mill in Iraq. They consist of a rotating cylinder that is filled with steel balls. The limestone is fed into the cylinder and is ground by the impact of the balls.

Ball mills are relatively inexpensive and easy to maintain. They are also relatively versatile and can be used to grind a variety of materials, including limestone, cement clinker, and fly ash.

However, ball mill can be inefficient for grinding coarse materials. The balls tend to bounce off the limestone particles, rather than grinding them into a fine powder.

Vertical Roller Mills

Vertical roller mills are becoming increasingly popular in Iraq for grinding limestone powder. They consist of two or more rollers that are arranged vertically. The limestone is fed between the rollers and is ground by the shearing action of the rollers.

Vertical roller mills are more efficient than ball mills for grinding coarse materials. The rollers are able to grind the limestone into a fine powder without bouncing off the particles.

However, vertical roller mills are more expensive than ball mills and require more maintenance.

Other Types of Limestone Powder Grinding Mills

In addition to ball mills and vertical roller mills, there are a number of other types of limestone powder grinding mills available. These include:

- Hammer mills: Hammer mills use hammers to grind the limestone. They are relatively inexpensive and easy to maintain, but they can be noisy and produce a dusty product.

- Attrition mills: Attrition mills use two or more rotating surfaces to grind the limestone. They are more efficient than ball mills for grinding fine materials, but they can be more expensive and require more maintenance.

- Impact mills: Impact mills use the impact of rotating hammers to grind the limestone. They are more efficient than ball mills for grinding coarse materials, but they can be noisy and produce a dusty product.

The type of limestone powder grinding mill that is best for a particular application will depend on a number of factors, including the size of the operation, the type of limestone to be ground, and the desired product specifications.