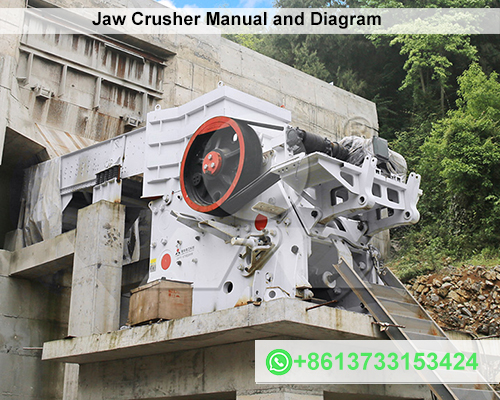

Jaw Crusher Manual and Diagram

Jaw crusher is one of the most commonly used pieces of equipment in the mining, construction, and recycling industries. They are primarily used for primary crushing, where large chunks of material, typically rocks or ores, are reduced in size to more manageable pieces for further processing. This article provides a detailed overview of jaw crusher, their operation, and a typical diagram to help users understand how the equipment functions. Whether you’re a seasoned operator or new to the field, this guide will give you essential information on using and maintaining jaw crusher.

1. Introduction to Jaw Crusher

A jaw crusher is a type of primary crusher used to break large rocks into smaller, more manageable sizes. The machine operates on a simple principle where material is compressed between two plates: a fixed plate and a moving plate (known as the jaw plate). The moving plate, also referred to as the swing jaw, moves back and forth, crushing the material by compressing it between the plates.

2. How a Jaw Crusher Works

The operation of a jaw crusher is based on the idea of compressive force. The material is fed into the crushing chamber, which is formed by the two plates (the fixed and the moving jaw). As the moving jaw closes, the material is crushed between the two plates, and the crushed material is discharged at the bottom of the chamber. The working motion of the jaw is typically a back-and-forth (reciprocating) motion that occurs due to the eccentric shaft’s rotation.

Key Components:

- Fixed Jaw Plate: The stationary surface that holds the material.

- Swing Jaw Plate: The movable surface that crushes the material.

- Eccentric Shaft: A rotating shaft that causes the swing jaw to move in a back-and-forth motion.

- Flywheel: A large, heavy wheel that stores energy and smoothens the motion of the crusher.

- Toggle Plate: A safety feature that absorbs shock and protects the machine from damage.

- V-belt Drive: The system that transmits power from the motor to the crusher.

3. Jaw Crusher Operation Manual

The operation manual of a jaw crusher provides step-by-step guidance for users on how to operate, maintain, and troubleshoot the machine. Here are some key points typically covered in a jaw crusher manual:

a) Initial Setup

- Ensure that the machine is installed correctly according to the manufacturer’s specifications.

- Proper alignment of the machine’s components is essential to prevent unnecessary wear.

- The base of the jaw crusher should be level and secure to prevent misalignment during operation.

b) Loading Material

- Feed material should be fed uniformly into the crushing chamber.

- Avoid overloading the crusher with oversized material, as this can cause damage to the machine.

- Ensure that the material size is within the machine’s capacity, as specified in the manual.

c) Operation Procedures

- Start the machine by activating the motor and allowing the flywheel to rotate.

- Monitor the gap between the fixed and swing jaw plates. The size of this gap determines the size of the output material.

- Adjust the discharge gap to ensure the desired output size.

d) Regular Maintenance

- Lubrication: Regularly lubricate the moving parts to reduce friction and wear.

- Check for wear and tear: Inspect the jaw plates, toggle plate, and other components for signs of wear. Replace them as needed.

- Inspect the flywheel and eccentric shaft for any damage that could affect the machine’s operation.

- Check the V-belts and ensure they are properly tensioned and not damaged.

e) Safety Measures

- Always operate the jaw crusher according to the manufacturer’s guidelines.

- Ensure that safety guards and covers are in place before operating the machine.

- Never place hands or other body parts near the crushing chamber when the machine is running.

f) Troubleshooting

- Overheating: If the jaw crusher is overheating, check the bearings, lubrication, and the motor.

- Uneven wear: If the jaw plates are wearing unevenly, check for alignment issues or excessive feed sizes.

- Reduced capacity: If the capacity drops, check for blockages, worn-out components, or improper settings in the crushing chamber.

4. Jaw Crusher Diagram

A diagram of a jaw crusher typically illustrates the key components and their relationships within the machine. Below is a description of the key parts that would typically be shown in a jaw crusher diagram:

- Feed Hopper: Where the raw material is loaded into the crusher.

- Feeding mechanism: Often a vibrating feeder that controls the flow of material into the crushing chamber.

- Fixed Jaw Plate (Stationary Plate): The part of the crusher that does not move. It is typically made of high-strength steel.

- Swing Jaw Plate (Moving Plate): The part that moves back and forth to crush the material.

- Eccentric Shaft: Located beneath the crusher, this rotating shaft moves the swing jaw in a circular motion.

- Flywheel: A large, heavy wheel that helps maintain the crusher’s momentum during operation.

- Toggle Plate: A part that connects the moving jaw to the eccentric shaft and absorbs shock during the crushing process.

- Discharge Port: Where the crushed material exits the crusher.

- Frame: The base structure that supports the jaw crusher components.

5. Common Jaw Crusher Models

There are several types of jaw crusher available, each suitable for different types of material processing. Some common models include:

- Single-toggle jaw crusher – These use a single moving jaw to crush material, which is simple in design and relatively low cost.

- Double-toggle jaw crusher – These use two moving jaws for increased crushing power, often used in applications where a higher throughput is required.

- Mobile jaw crusher – These are mounted on tracks or wheels for easy movement on-site, offering flexibility in construction or demolition projects.

6. Conclusion

Jaw crusher is essential equipment in many industries, particularly for breaking down large, tough materials like rock, ore, and concrete. Understanding the operation of a jaw crusher, as well as its manual and diagram, is crucial for maximizing efficiency and ensuring safety. By following the manufacturer’s instructions for operation and maintenance, users can ensure that their jaw crusher remains in top working condition, providing reliable performance for years to come.