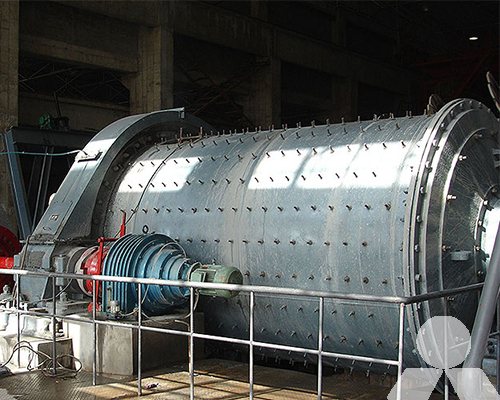

Schematic diagram of ball mill

A ball mill is a type of grinder used to grind and blend materials for use in mineral processing, ceramics, paints, and other industries. It operates on the principle of impact and attrition, where the grinding media (balls) cascade within the mill, generating comminution of the material. This article explains the working principle of a ball mill, illustrating the stages of the process and highlighting its significance in various applications.

Working Principle: The ball mill consists of a cylindrical shell that rotates around its axis. Inside the cylinder, different grinding media, such as steel balls, ceramic pebbles, or natural stones, collide with the material to be ground. The cylindrical shell is usually partially filled with the grinding media and the material to be ground, creating a cascading effect as the cylinder rotates.

- Loading: The material to be ground is introduced into the mill through a feed chute or hopper. The size of the material typically ranges from small particles to larger chunks, depending on the specific application.

- Grinding: As the cylinder rotates, the grinding media cascade and fall, impacting and crushing the material. The kinetic energy from the falling media is transferred to the material, causing it to break into smaller particles. The impact force is responsible for reducing the size of the material, and the grinding media themselves also wear down over time due to repeated impacts.

- Attrition: In addition to impact, attrition also plays a significant role in the grinding process. The grinding media rub against each other and against the material, leading to further size reduction. This rubbing action generates heat, which can affect the material properties.

- Fineness Control: The fineness of the ground material can be controlled by adjusting factors such as the rotational speed of the mill, the size and composition of the grinding media, and the residence time of the material inside the mill. Finer materials require longer grinding times and higher rotational speeds, while coarser materials need less grinding time.

- Discharge: Once the material reaches the desired fineness, it is discharged from the mill through the discharge chute. The ground material may then undergo further processing or be used directly in various applications.

Significance and Applications: The ball mill’s working principle finds applications in various industries. In mineral processing, it is used for grinding ores to extract valuable minerals. In the pharmaceutical and chemical industries, it is employed to reduce the particle size of active ingredients and chemicals. Additionally, the ball mill is crucial in the production of ceramics, where finely ground materials are used to create glazes and porcelain products.

The ball mill’s working principle revolves around impact and attrition, providing an effective means of reducing particle size in various industries. By understanding this principle, engineers and operators can optimize the grinding process to achieve the desired product characteristics and quality.