Compressive Strength of Concrete Crusher Machine

Concrete is an indispensable material in the construction of buildings, bridges, roads, and other infrastructures due to its strength and durability. One of the primary properties that engineers evaluate is its compressive strength, which reflects its capacity to resist axial loads without breaking. Testing this strength is crucial for ensuring the material meets the required standards for safety and performance.

A concrete crusher machine is an essential tool in determining the compressive strength of concrete. These machines are designed to apply controlled compressive loads to concrete samples, typically cubes or cylinders, to measure how much force they can endure before failure. This article will discuss the working principles, types, and significance of concrete crusher machines in evaluating the compressive strength of concrete.

Principles of Compressive Strength Testing

The compressive strength of concrete is typically measured in megapascals (MPa) or pounds per square inch (psi). The testing process involves placing a prepared concrete sample in the crusher machine, which applies compressive force at a controlled rate. The machine measures the force applied and the point at which the concrete specimen fails or cracks. This value is recorded as the compressive strength of the material.

The concrete samples used for testing are commonly in the form of cylinders or cubes, typically prepared and cured for 28 days. The sample size and curing conditions play a critical role in the final strength measurements.

Types of Concrete Crusher Machines

There are several types of crusher machines used to test the compressive strength of concrete. The most common include:

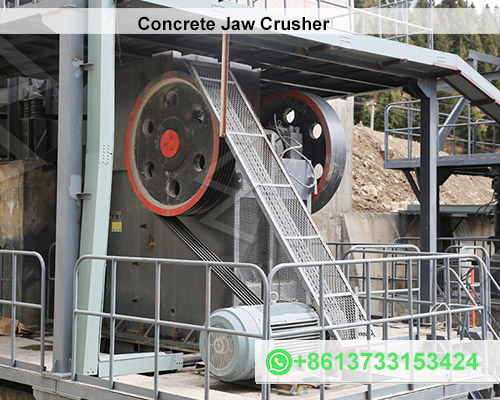

- Jaw Crushers

Jaw crusher is the simplest and most widely used crushers in concrete strength testing. These machines apply compressive force between two rigid surfaces (the jaws), crushing the concrete sample into smaller fragments. Jaw crusher is particularly effective for large and hard concrete specimens. - Cone Crushers

Cone crusher is often used for fine crushing of concrete samples. They work by squeezing the material between a gyrating cone and a fixed outer surface. Cone crusher is preferred for medium to high-strength concrete and offer precision in breaking down materials to specific sizes. - Impact Crushers

Impact crushers utilize high-speed impact force to break concrete samples. Though less common in strength testing, they are useful for assessing the resistance of concrete to dynamic forces, such as those encountered during an impact or collision. - Hydraulic Compression Machines

Hydraulic compression machines are the most common type of crusher for testing the compressive strength of concrete. These machines apply a controlled, steady load on the concrete sample until failure occurs. They are capable of providing highly accurate strength measurements and are standard equipment in most laboratories.

Importance of Crusher Machines in Quality Control

Concrete crusher machines are vital for construction quality control. Engineers rely on the data from compressive strength tests to determine whether concrete batches meet project specifications. Testing ensures that the concrete can withstand the structural loads required for specific applications, such as foundations, columns, beams, and slabs.

Additionally, crusher machines help identify any defects in the concrete, such as improper curing, air voids, or inconsistent mixture proportions. By analyzing the failure patterns and strength values, engineers can adjust the concrete mix design or construction process to improve future performance.

The compressive strength of concrete is one of the most critical parameters in construction engineering, directly influencing the durability and safety of structures. Concrete crusher machines play a pivotal role in assessing this strength, providing essential data for quality control and ensuring compliance with building codes and standards.

Different types of crushers, including jaw, cone, impact, and hydraulic machines, are used depending on the specific requirements of the test. With ongoing advancements in technology, crusher machines are becoming more accurate, efficient, and user-friendly, further enhancing the reliability of compressive strength testing. Proper use of these machines is fundamental to ensuring the integrity and longevity of concrete structures worldwide.