Grinding Principle and Method of Raymond Mill

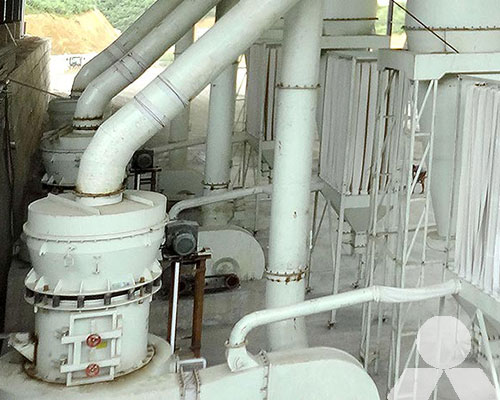

Raymond Mill is a widely used grinding equipment for various materials, such as minerals, ores, and chemicals. It operates on the principle of pendulum grinding, which means that the grinding roller assembly rotates around the center axis and swings outward under the action of centrifugal force. The material is fed into the grinding chamber between the grinding roller and the grinding ring, and as the grinding roller rolls, it crushes and grinds the material.

The grinding principle of Raymond Mill can be summarized as follows:

- Crushing: The raw material is crushed into smaller particles by the jaw crusher or hammer crusher to the required feed size.

- Grinding: The crushed material is conveyed into the grinding chamber of the Raymond Mill. The grinding roller assembly, consisting of grinding rollers, hanger brackets, and main shaft, rotates around the central axis, and the grinding rollers press against the grinding ring. The material is ground between the grinding roller and the grinding ring. The grinding rollers themselves also rotate around their own axis, while rolling on the grinding ring.

- Classification: After grinding, the fine particles are carried away by the airflow through the classifier, while the coarse particles fall back down to the grinding chamber for regrinding. The classified fine particles are collected and discharged through the discharge device.

The grinding method of Raymond Mill involves a combination of compression, impact, and shearing forces. The grinding rollers exert pressure on the material, crushing it against the grinding ring. The material is also impacted by the centrifugal force generated by the rotation of the grinding rollers. Additionally, the grinding rollers themselves rotate and roll on the grinding ring, shearing the material and facilitating the grinding process.

The key factors affecting the grinding efficiency and final product quality of Raymond Mill include the feed size, grinding roller pressure, grinding ring diameter, grinding roller and ring wear, and the airflow rate and classifier speed for classification.

It is important to note that the above description provides a general overview of the grinding principle and method of Raymond Mill. The specific operation and settings may vary depending on the design and configuration of the Raymond Mill and the characteristics of the material being processed. It is always recommended to refer to the manufacturer’s instructions and guidelines for proper usage and optimization of the grinding process.