News

Last Updated :2023-07-11

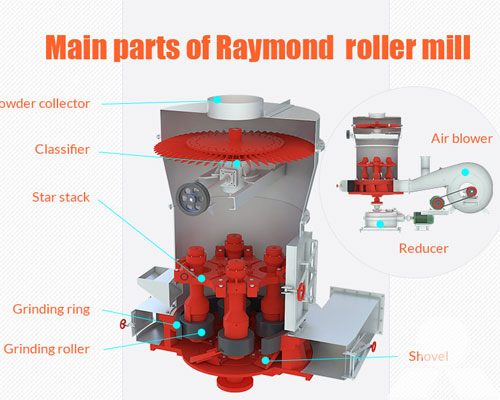

Operational Details of the Raymond Mill

Raymond mill, also known as Raymond roller mill, is a commonly used grinding equipment for various minerals and materials in industries such as mining, metallurgy, building materials, and chemical engineering. Here are some operational details of the Raymond mill:

- Working Principle: The Raymond mill works by grinding the material between the grinding roller and the grinding ring. The grinding roller rolls on the grinding ring under the action of centrifugal force, and the material is ground between the grinding roller and the grinding ring.

- Grinding Ring and Grinding Roller: The grinding ring and grinding roller are the key components of the Raymond mill. They are made of high-quality materials with wear-resistant and heat-resistant properties to ensure long-term operation.

- Feeding and Discharging: The material to be ground is fed into the Raymond mill through the feeding device and is evenly and continuously conveyed to the grinding chamber. The ground material is then discharged through the discharging device.

- Grinding Chamber: The grinding chamber of the Raymond mill is where the grinding occurs. It contains the grinding roller, grinding ring, blade, and other components. The grinding chamber is designed to create a vortex-like airflow, which helps to carry the ground material out of the mill.

- Classifier: The Raymond mill is equipped with a classifier, which controls the fineness of the finished product. The classifier separates the fine particles from the coarse particles and directs them into different outlets. The fineness of the product can be adjusted by changing the rotational speed of the classifier or adjusting the clearance of the classifier blades.

- Air Blower: The Raymond mill has an air blower that supplies the airflow needed for the grinding process. The air blower delivers the air into the grinding chamber, where it helps to carry the ground material and remove the excess moisture.

- Electromagnetic Vibrating Feeder: In some Raymond mill configurations, an electromagnetic vibrating feeder is used to control the feeding of the material. The feeder ensures a continuous and uniform feed of the material into the mill.

- Control System: The Raymond mill may have a control system that allows operators to adjust various parameters such as grinding fineness, grinding pressure, and feed rate. The control system helps to optimize the operation of the mill and ensure consistent performance.

It’s important to note that the operational details of a specific Raymond mill may vary depending on the model and manufacturer. Therefore, it’s advisable to refer to the manufacturer’s instructions and guidelines for the specific Raymond mill being used.