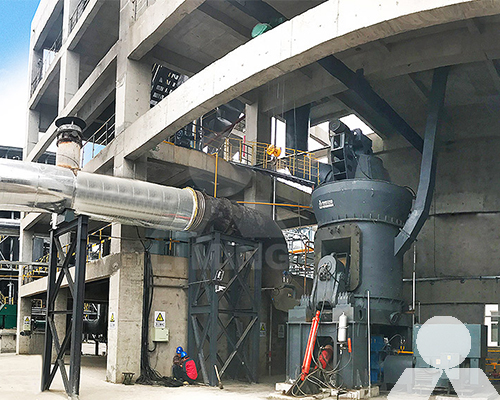

Ultrafine grinding dry grinding mill works and classification

Ultrafine grinding mill is essential equipment in various industries, playing a pivotal role in reducing solid materials to extremely fine particles. These mills are commonly used in fields such as pharmaceuticals, food processing, mining, and materials science. This article will explore the working principles and classifications of ultrafine grinding mills.

Working Principles

The fundamental principle behind ultrafine grinding mills is the reduction of particle size through mechanical forces. These mills employ various techniques to achieve this, including impact, shear, compression, and attrition. Here are the primary working principles of ultrafine grinding mills:

- Impact: In impact mills, particles are subjected to high-speed impacts from hammers, rods, or pins. This results in particle fragmentation and size reduction.

- Shear: Shearing forces are applied to the material by rotating or reciprocating blades. This causes materials to be sliced or sheared into smaller particles.

- Compression: Some mills utilize compressive forces to crush and reduce particle size. This is achieved by applying pressure between two surfaces or rolls.

- Attrition: Attrition mills use grinding media, such as balls or beads, to wear down and reduce particle size through repeated collisions and friction.

Classification of Ultrafine Grinding Mills

Ultrafine grinding mills can be categorized based on their design, operating principles, and the type of materials they are best suited for. Here are some common classifications:

- Ball Mills: Ball mills are widely used for grinding solid materials by rotating a container filled with balls. They are common in mining and ceramics industries and are versatile in reducing various materials to fine powders.

- Fluid Energy Mills: These mills use a high-velocity jet of compressed gas to impact particles, resulting in size reduction. Fluid energy mills are effective for grinding heat-sensitive materials.

- Hammer Mills: Hammer mills rely on the impact of hammers to crush and pulverize materials. They are widely used in food processing and agricultural applications.

- Roller Mills: Roller mills use cylindrical rollers to crush and grind materials. They are suitable for reducing a wide range of materials, including grains, minerals, and chemicals.

Ultrafine grinding mills are integral to many industrial processes, enabling the production of fine powders and nanoparticles. Their working principles encompass a range of mechanical forces, including impact, shear, compression, and attrition. These mills come in various types and designs, each tailored to specific applications and material characteristics. Understanding the principles and classifications of ultrafine grinding mills is essential for selecting the most suitable equipment for a given task in different industries.