T130X Superfine Grinding Mill

T130X Superfine Grinding Mill evolves from TGM Super Pressure Trapezium Mill which has got many patents. The demand for finely ground materials has increased significantly in industries such as mining, metallurgy, chemical engineering, and construction. Traditional grinding mills often face limitations in achieving the desired particle size distribution due to their inadequate performance in fine grinding. The emergence of the T130X Superfine Grinding Mill has revolutionized the field of particle size reduction, offering advanced features and capabilities.

Input Size: 0-30mm

Capacity: 4-14TPH

Material: Cement, coal, power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

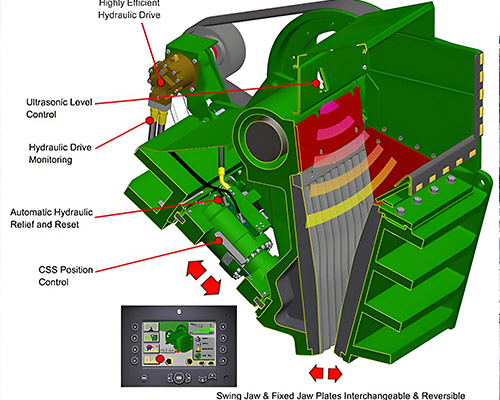

Features and Working Principles

T130X Superfine Grinding Mill incorporates several key features that distinguish it from conventional grinding mills. These features include an advanced classifier system, high-efficiency impeller, and a robust grinding chamber. The mill utilizes centrifugal force, impact, and shear forces to achieve efficient grinding. The materials are fed into the mill through the feeding system, and the grinding process is controlled by the rotation speed of the main shaft, adjustable separator fineness, and other parameters.

Advantages and Applications

T130X Superfine Grinding Mill offers several advantages over traditional grinding mills. Firstly, it provides superior control over particle size distribution, allowing for the production of materials with a narrow size range. This enables manufacturers to meet stringent quality specifications and enhance product performance. Secondly, the mill exhibits high grinding efficiency, reducing energy consumption and operational costs. Additionally, the T130X Superfine Grinding Mill is versatile and can process a wide range of materials, including minerals, chemicals, and construction aggregates.

Challenges and Potential Solutions

While the T130X Superfine Grinding Mill offers numerous advantages, certain challenges need to be addressed for its successful implementation. These challenges include maintaining stable operation, preventing equipment wear and tear, and managing the disposal of fine particles generated during the grinding process. Manufacturers can overcome these challenges through regular maintenance, adopting appropriate grinding media, and implementing effective dust collection systems.

Sustainability Considerations

T130X Superfine Grinding Mill aligns with the growing emphasis on sustainable manufacturing practices. By optimizing grinding efficiency and reducing energy consumption, the mill contributes to lower carbon emissions and reduced environmental impact. Furthermore, the precise control over particle size distribution minimizes material waste and enhances resource utilization.

Product Parameters