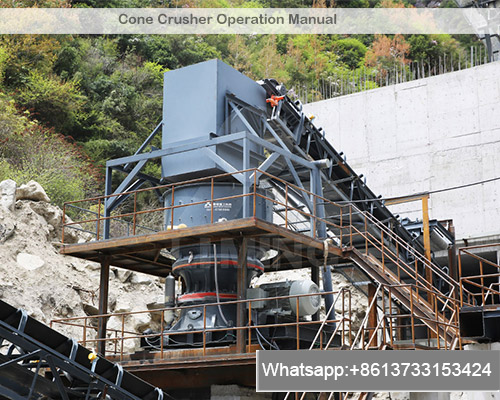

Cone Crusher Operation Manual

1. Introduction

Cone crusher are a type of rock crusher that uses a rotating cone-shaped head to crush material. They are commonly used in the mining, quarrying, and construction industries. Cone crusher are efficient and versatile, and they can be used to crush a wide variety of materials, including hard rock, gravel, and sand.

2. Safety

Before operating a cone crusher, it is important to read and understand the operator’s manual. The manual will provide specific instructions for the safe operation of the machine. It is also important to wear the appropriate personal protective equipment (PPE), including a hard hat, safety glasses, earplugs, and gloves.

3. Pre-operation checks

Before starting the cone crusher, it is important to perform a number of pre-operation checks. These checks include:

- Checking the hydraulic oil level

- Checking the coolant level

- Checking the grease levels

- Inspecting the belts for wear and damage

- Checking the safety guards for damage

- Ensuring that the feed hopper is empty

4. Starting the cone crusher

Once the pre-operation checks have been completed, the cone crusher can be started. The starting procedure will vary depending on the specific machine, but it will typically involve starting the hydraulic pump and then starting the cone head.

5. Operating the cone crusher

The cone crusher is operated by adjusting the feed rate and the gap setting. The feed rate is the amount of material that is fed into the crusher at one time. The gap setting is the distance between the cone head and the liner. The feed rate and gap setting should be adjusted to achieve the desired product size.

6. Stopping the cone crusher

To stop the cone crusher, the feed hopper should be emptied and then the cone head should be stopped. The hydraulic pump should then be stopped.

7. Maintenance

Cone crusher require regular maintenance to ensure that they operate safely and efficiently. The maintenance schedule will vary depending on the specific machine, but it will typically include:

- Checking the hydraulic oil level and changing the hydraulic oil as needed

- Checking the coolant level and changing the coolant as needed

- Greasing the bearings

- Inspecting the belts for wear and damage

- Checking the safety guards for damage

- Inspecting the liner for wear and replacing the liner as needed

8. Troubleshooting

If the cone crusher is not operating properly, there are a number of things that can be done to troubleshoot the problem. Some common problems and their solutions include:

- The crusher is not feeding properly: This could be caused by a problem with the feed hopper, the feed conveyor, or the hydraulic system.

- The crusher is not crushing the material properly: This could be caused by a problem with the gap setting, the liner, or the hydraulic system.

- The crusher is making strange noises: This could be caused by a problem with the bearings, the belts, or the hydraulic system.

If the problem cannot be solved by following the troubleshooting steps in the operator’s manual, the manufacturer should be contacted.

Cone crusher are a valuable tool for the mining, quarrying, and construction industries. By following the safety instructions and operating the machine properly, cone crusher can provide years of reliable service.