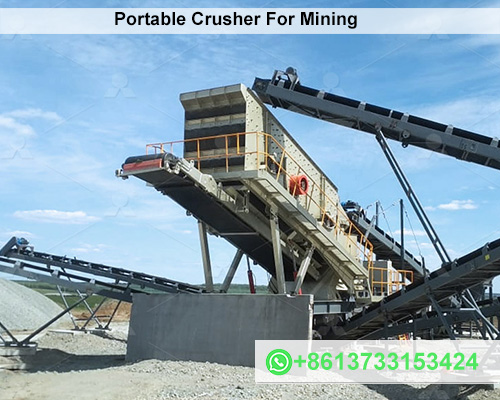

Portable Crusher For Mining

Portable crusher have transformed the mining industry by introducing flexibility and efficiency to the traditionally stationary crushing processes. These powerful machines allow mining operations to move, process, and extract minerals on-site, providing a solution that minimizes transportation needs, saves on labor costs, and boosts productivity. This article explores the features, benefits, types, and applications of portable crusher in the mining sector.

1. What is a Portable Crusher?

A portable crusher, sometimes called a mobile crusher, is a machine designed to reduce large rocks into smaller pieces and is equipped to be moved across mining sites. Unlike stationary crusher, which require a fixed foundation, portable crusher can be transported directly to various parts of a mining site, making them ideal for operations that span large or dynamic areas.

Portable crusher is mounted on wheels, tracks, or trailers, making them easy to relocate and set up as needed. They can handle a range of materials, including ores, rocks, and other minerals, enabling mining companies to process raw materials closer to the source of extraction.

2. Key Components of Portable Crusher

Portable crusher generally include several key components that enable their mobility and crushing power:

- Feeder:A vibrating feeder controls the flow of materials into the crusher.

- Crusher Unit:The heart of the machine, the crusher unit is responsible for the actual crushing process. Various types of crusher units, such as jaw crusher, cone crusher, impact crusher, and hammer crusher, can be integrated into portable setups.

- Screen:Some portable crusher come with integrated screens to separate different material sizes after crushing.

- Conveyor:A conveyor system moves the crushed material away from the crusher and can be configured to transport materials to different stages.

- Power Source:Portable crusher may use diesel engines, electric motors, or hybrid power systems for energy.

3. Types of Portable Crusher in Mining

Several types of portable crusher is used in mining, each designed to handle specific materials and crushing requirements:

- Jaw Crusher:Jaw crusher is widely used for primary crushing in mining operations. They apply compressive force to break down large rocks into smaller pieces, making them suitable for hard and abrasive materials.

- Cone Crusher:Often used for secondary crushing, cone crusher is efficient at breaking down medium-hard materials like granite, iron ore, and copper ore. They offer high reduction ratios and are suitable for use after jaw crusher.

- Impact Crusher:Impact crusher is ideal for softer materials and recycling applications. They use impact force to break down materials and are especially popular for limestone, concrete, and softer mineral ores.

- Hammer Crusher:These crusher use rotating hammers to impact and crush materials, making them suitable for a variety of mining materials, including gypsum and coal.

- Roll Crusher:Roll crusher work by compressing materials between two rotating rollers. They’re effective in mineral processing and are typically used for smaller operations.

Each type has its advantages and is selected based on the hardness of the material, desired size of output, and processing capacity requirements.

4. Advantages of Using Portable Crusher

Portable crusher offer several benefits over stationary crushing systems:

- Increased Flexibility:They allow for easy relocation, enabling mining companies to adapt to changing mining site requirements and extract materials from multiple locations.

- Reduced Transportation Costs:Crushing materials closer to the extraction point reduces the need for expensive transportation, minimizing fuel costs and reducing environmental impact.

- Operational Efficiency:Portable crusher streamline operations by reducing setup time and simplifying logistical needs, which can lead to faster project timelines.

- Lower Capital Investment:Portable crusher eliminate the need for extensive foundations and permanent infrastructure, which can lead to lower upfront capital costs compared to stationary crusher.

- Environmental Benefits:By minimizing material transport, portable crusher help reduce the carbon footprint of mining operations and align with sustainability goals.

5. Applications in the Mining Industry

Portable crusher is versatile and can be used in various mining applications, including:

- Open-Pit Mining:In large-scale open-pit mining, portable crusher can be stationed directly at the site, allowing materials to be processed near the extraction area, thereby minimizing material handling costs.

- Underground Mining:Portable crusher is beneficial in underground mining where space is limited. Smaller portable crusher can be used in tunnels to process extracted material immediately, helping to keep operations efficient and less congested.

- Aggregate Production:Mining operations often require aggregate materials for construction and road building. Portable crusher can be set up on-site to provide a steady supply of gravel and other aggregates.

- Ore Processing:Portable crusher is widely used to process ores at different stages of production. They can crush primary materials extracted from the earth, providing consistent sizing for further refinement or chemical processing.

- Construction Waste Recycling:Many mining sites also generate construction waste. Portable crusher can repurpose waste materials, reducing the need for landfills and turning waste into usable material.

6. Choosing the Right Portable Crusher

When selecting a portable crusher, mining companies should consider the following factors:

- Material Characteristics:The hardness, abrasiveness, and moisture content of the material can dictate the type of crusher best suited for the job.

- Output Size Requirements:Different crusher produce different output sizes. The required particle size should match the crusher’s capabilities.

- Capacity Needs:The expected production volume will influence the size and type of crusher chosen.

- Mobility Requirements:Consider how often the crusher needs to be relocated. Track-mounted crusher offer greater flexibility for frequent relocations, while wheel-mounted crusher can be easier to transport over long distances.

- Power Source:The availability of electricity on-site can determine whether an electric, diesel, or hybrid-powered crusher is best suited for the operation.

7. Future Trends in Portable Crusher for Mining

The mining industry is leaning toward more energy-efficient, technologically advanced equipment. Innovations in portable crusher is emerging to meet these demands:

- Automation and Remote Monitoring:Advanced systems now include automation features that can be controlled remotely, allowing operators to adjust settings, monitor performance, and address issues without needing to be physically present.

- Sustainable Power Sources:Hybrid and fully electric portable crusher is growing in popularity as mining companies seek ways to reduce their environmental footprint and energy costs.

- Improved Mobility and Compact Designs:Future portable crusher is expected to be even more compact, flexible, and easier to deploy in diverse environments, including rugged and remote locations.

Conclusion

Portable crusher have become an indispensable asset in modern mining. They provide operational flexibility, cost savings, and increased efficiency while supporting sustainable mining practices. As the mining industry continues to evolve, portable crusher will play a pivotal role in shaping efficient and environmentally friendly mining operations. Whether in open-pit, underground, or aggregate applications, these versatile machines are a valuable tool in the global push toward more adaptive and resourceful mining practices.