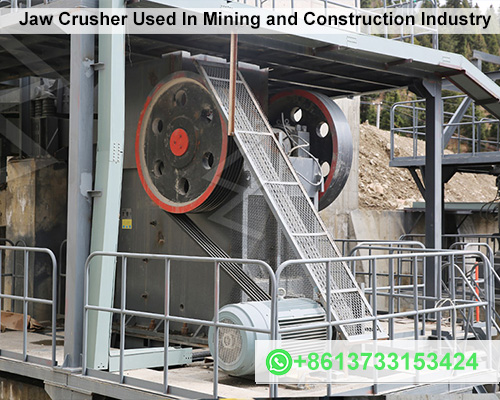

Jaw Crusher Used in the Mining and Construction Industry

Jaw crusher is a fundamental piece of heavy equipment used in various industries, notably mining, construction, and metallurgy. They are critical in breaking down large rocks and ores into smaller, more manageable sizes. This article explores the functions, types, applications, and advantages of jaw crusher, highlighting their importance in modern industry.

What is a Jaw Crusher?

A jaw crusher is a type of compression machine that reduces the size of materials, primarily hard minerals and rocks, by compressing them between a fixed and a moving jaw plate. The movement mimics the action of a human jaw, where one side remains stationary while the other moves back and forth, crushing the material with each motion.

The crushing process involves a few key steps:

- Feeding: The material enters the top of the crusher.

- Compression: The moving jaw exerts force against the material, crushing it between the two plates.

- Discharge: The crushed material is released through the bottom, ready for further processing or use.

Types of Jaw Crusher

There are several types of jaw crusher available, each suited for different applications:

- Primary Jaw Crusher: Used for the initial phase of material reduction, where large stones and ores are crushed into smaller, manageable pieces.

- Secondary Jaw Crusher: Often used after a primary crusher, this type helps achieve finer particle sizes.

- Single Toggle Jaw Crusher: Features a single moving jaw that crushes material against a fixed surface. Known for its simple structure and ease of operation, this type is widely used.

- Double Toggle Jaw Crusher: Has two moving jaws, which offer greater crushing force and efficiency. It’s suitable for handling very tough and abrasive materials.

Applications of Jaw Crusher

Jaw crusher is versatile and can be used in a variety of industrial applications:

- Mining: Jaw crusher is extensively used to crush hard rocks and ores such as granite, iron ore, and gold ore. By reducing large rocks to smaller sizes, they help streamline mining operations, making it easier to transport materials for further processing.

- Construction: They play a significant role in recycling materials like concrete and bricks. In construction demolition, jaw crusher enable the effective crushing of concrete and asphalt into reusable aggregates.

- Aggregates and Sand Production: In the production of sand and gravel, jaw crusher serve to break down larger stones into smaller pieces, facilitating the creation of materials for construction and roadwork.

Advantages of Using Jaw Crusher

Jaw crusher offer several advantages, making them invaluable in many industrial settings:

- High Efficiency and Durability: Built from strong materials, jaw crusher can handle large loads and maintain performance over prolonged periods.

- Low Operational Cost: With relatively simple designs and robust components, jaw crusher require minimal maintenance, making them cost-effective over time.

- Versatility: Able to crush a wide range of materials, from soft minerals to very hard rocks, they offer flexibility in diverse applications.

- Easy Installation and Operation: These machines are straightforward to set up and operate, requiring minimal technical expertise, making them accessible for use in various industries.

The Working Principle of Jaw Crusher

The operation of a jaw crusher is straightforward. Here’s a breakdown of its key components and their functions:

- The Feed Opening: This is where the material enters the crusher, and its size determines the maximum feed size the crusher can handle.

- Fixed Jaw Plate: Serves as the base where the material is pressed against.

- Moving Jaw Plate: Moves in a back-and-forth motion, compressing the material against the fixed jaw.

- Toggle Plate: Ensures the necessary motion for the jaw movement, allowing it to swing for effective compression.

Once the material is reduced to the desired size, it falls through the bottom opening, where it can either be transported for further processing or used directly.

Limitations and Challenges

While jaw crusher is versatile, they are not suited for all crushing needs. They generally cannot achieve extremely fine particle sizes, and for materials with a high level of abrasiveness, maintenance costs can rise due to wear and tear on the plates. Additionally, for operations requiring precise particle size control, other crusher, such as cone or impact crusher, may be more effective.

Conclusion

Jaw crusher play a vital role in the mining, construction, and aggregate industries, offering a powerful solution for breaking down tough materials. With their rugged design, ease of operation, and versatility, they are highly regarded for handling a wide range of applications. However, understanding the specific requirements and conditions of each project is crucial for selecting the most suitable jaw crusher model.

For industries that need reliable, robust, and efficient crushing machinery, jaw crusher is indispensable tools. Whether in a large mining operation or a smaller construction project, they continue to prove their worth as essential equipment in modern industry.