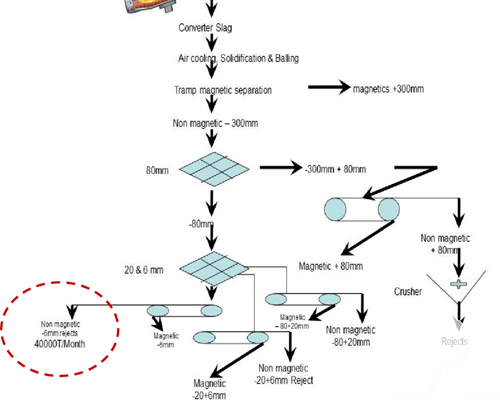

Slag Crusher Flow Charts

Slag crusher are used to crush slag, which is a waste product from various industrial processes. The slag can be from steelmaking, ironmaking, or other metal production processes. Slag crushers are used to reduce the size of the slag so that it can be recycled or disposed of more easily.

There are many different types of slag crushers available, each with its own advantages and disadvantages. The most common type of slag crusher is the jaw crusher. Jaw crushers are simple and relatively inexpensive to operate. They are also relatively efficient at crushing slag.

Another type of slag crusher is the cone crusher. Cone crusher are more efficient than jaw crushers at crushing hard materials. However, they are also more expensive to operate.

The specific flow chart for a slag crusher system will vary depending on the type of slag crusher used and the desired size of the crushed slag. However, there are some common elements that are found in most slag crusher systems.

Typical Slag Crusher Flow Chart

The first step in the slag crusher system is to feed the slag into the crusher. The slag can be fed into the crusher by a conveyor belt or a bucket elevator.

Once the slag is in the crusher, it is crushed by the rotating jaws or cone. The crushed slag is then discharged from the crusher.

In some cases, the crushed slag may need to be screened to remove any oversized particles. The screened slag is then ready for recycling or disposal.

Applications of Slag Crushers

Slag crushers are used in a variety of industries, including:

- Steelmaking

- Ironmaking

- Metal production

- Construction

- Mining

Slag crushers are an important part of the recycling and disposal of slag. They help to reduce the environmental impact of slag by making it easier to recycle or dispose of.