Talcum powder grinding manufacturing process

Talcum powder is a soft, white mineral that is used in a variety of products, including baby powder, cosmetics, and paints. It is made by grinding talc ore into a fine powder.

The talcum powder grinding manufacturing process can be divided into the following steps:

1. Mining

Talc ore is mined from open-pit mines or underground mines. The mining process involves blasting the ore loose, loading it onto trucks, and transporting it to a processing plant.

2. Crushing

The talc ore is crushed into smaller pieces using a jaw crusher or a gyratory crusher. The crushed ore is then screened to remove any oversize pieces.

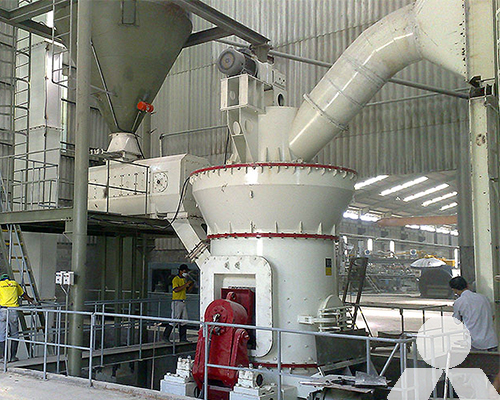

3. Grinding

The crushed ore is ground into a fine powder using a ball mill or a Raymond mill. The grinding process is typically done in two stages: a primary grind and a secondary grind.

4. Classification

The ground talcum powder is classified to remove any oversize particles. This is done using a classifier, such as an air classifier or a screen classifier.

5. Drying

The classified talcum powder is dried using a dryer, such as a rotary dryer or a fluidized bed dryer.

6. Packaging

The dried talcum powder is packaged in bags or drums.

7. Quality control

The talcum powder is tested to ensure that it meets the required specifications. This includes testing for particle size, brightness, and purity.

The talcum powder grinding manufacturing process is a relatively simple process. However, it is important to ensure that the process is controlled to produce a high-quality product.