SP Series Vibrating Feeder

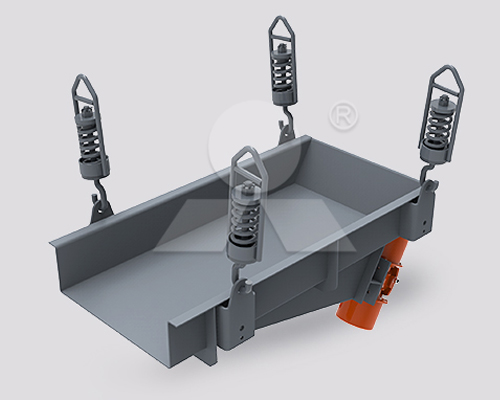

SP Series Vibratory Feeder is a new type of Vibratory Feeder specially designed by Coffeida for the feeding of secondary and tertiary crushers and the feeding of belt conveyor under the regulating yard and silo.The effective handling and controlled feeding of bulk materials are crucial in numerous industries, such as mining, construction, and metallurgy. Vibrating feeders play a vital role in these sectors by efficiently conveying and distributing materials. The SP Series Vibrating Feeder, developed by Liming Heavy Industry, represents a cutting-edge solution designed to address the challenges of material handling and provide significant operational benefits.

Input Size: 0-500mm

Capacity: 180-850TPH

Material: granite, marble, basalt, limestone, quartzite, pebble, copper ore, iron ore, coal, etc.

Key Features

SP Series Vibrating Feeder incorporates several key features that set it apart from traditional vibrating feeders. These features include:

- a. High-strength and durable construction: The feeder is constructed with high-quality materials, ensuring long-lasting performance even under harsh operating conditions.

- b. Adjustable feed rate: The feed rate of the SP Series Vibrating Feeder can be easily adjusted according to specific requirements, allowing for precise and controlled material delivery.

- c. Smooth and stable operation: The feeder’s design minimizes vibration transfer to the supporting structure, resulting in smooth and stable operation with reduced noise levels.

- d. Reliable and efficient performance: The feeder’s robust design, coupled with advanced vibration technology, ensures reliable and efficient material handling, minimizing downtime and maximizing productivity.

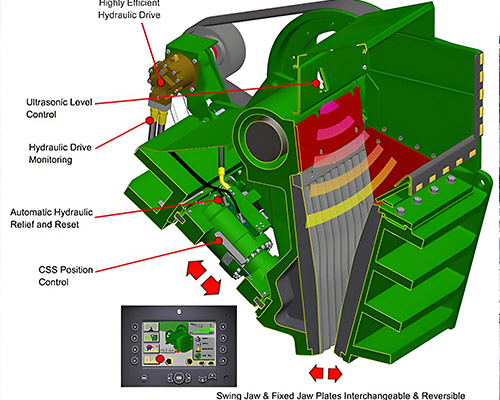

Working Principles

SP Series Vibrating Feeder operates on the principle of vibrating motion generated by an eccentric shaft. The vibrating motion conveys the material along the trough, resulting in smooth and controlled material flow. The feeder’s amplitude and frequency can be adjusted to optimize the feeding process, ensuring an even and consistent flow of materials.

Operational Advantages

SP Series Vibrating Feeder offers several operational advantages over traditional vibrating feeders:

- a. Increased feeding efficiency: The feeder’s adjustable feed rate and precise control enable optimal material flow, reducing the risk of blockages and ensuring consistent feeding.

- b. Enhanced equipment protection: The feeder’s gentle handling of materials minimizes wear and tear on downstream equipment, prolonging their operational lifespan.

- c. Reduced energy consumption: The efficient design of the SP Series Vibrating Feeder minimizes energy consumption, contributing to cost savings and environmental sustainability.

- d. Easy maintenance and servicing: The feeder’s modular design allows for easy maintenance and replacement of components, reducing downtime and improving overall operational efficiency.

Application Scenarios

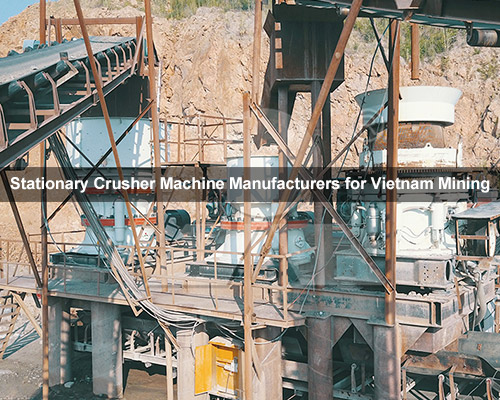

SP Series Vibrating Feeder finds application in various industries, including:

- a. Mining and quarrying: The feeder efficiently transports and feeds bulk materials, such as ores, minerals, and aggregates, to crushers, screens, and other processing equipment.

- b. Construction and demolition: The feeder facilitates the controlled feeding of construction debris and recycled materials, optimizing the efficiency of recycling processes.

- c. Metallurgy and steel production: The feeder handles the precise feeding of raw materials, such as iron ore and coke, to furnaces, ensuring consistent and efficient metal production.

- d. Chemical and pharmaceutical industries: The feeder is used for the controlled delivery of powders, granules, and other materials in chemical and pharmaceutical manufacturing processes.

Product Parameters