Gold Beneficiation Equipments

Gold beneficiation is the process of extracting gold from its ore. It is a complex process that involves several stages, each of which requires specialized equipment.

Common Gold Beneficiation Equipments

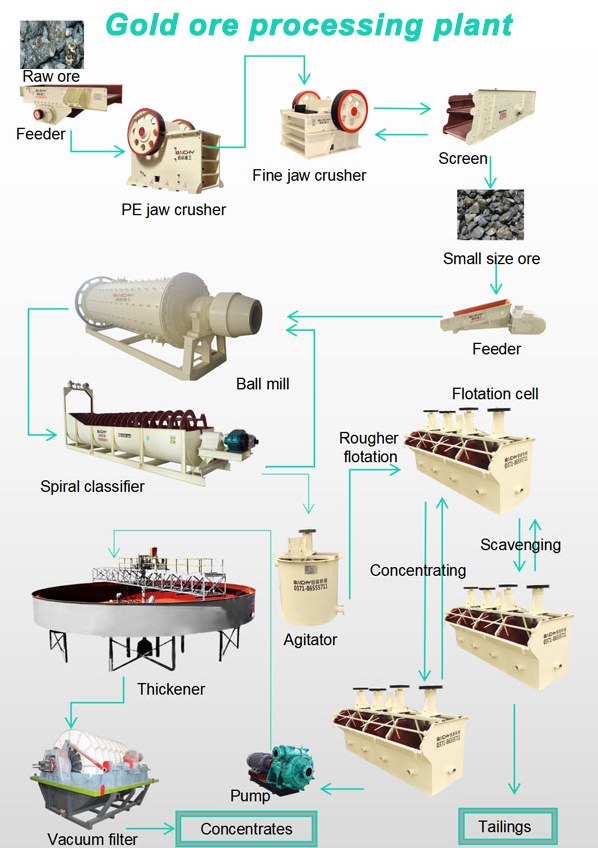

- Crushing and Grinding Equipment: These machines break down the ore into smaller pieces, making it easier to extract the gold. Common types of crushing and grinding equipment include jaw crusher, gyratory crusher, ball mills, and rod mills.

- Screening Equipment: Screens are used to separate the ore into different sizes. This is important because different sized particles require different processing methods. Common types of screening equipment include trommels, grizzly screens, and vibrating screens.

- Gravity Separation Equipment: Gravity separation is a method of separating gold from other minerals based on their density. Common types of gravity separation equipment include jigs, shaking tables, and spirals.

- Flotation Equipment: Flotation is a method of separating gold from other minerals based on their surface properties. Common types of flotation equipment include flotation cells and mechanical cells.

- Thickening and Dewatering Equipment: Thickening and dewatering equipment is used to remove water from the ore slurry. This is important because it makes the ore easier to transport and process. Common types of thickening and dewatering equipment include thickeners, filters, and centrifuges.

- Refining Equipment: Refining equipment is used to remove impurities from the gold concentrate. Common types of refining equipment include smelters, electrolytic cells, and cupels.

Factors to Consider When Choosing Gold Beneficiation Equipments

The type of gold beneficiation equipment that is required will depend on a number of factors, including the type of ore, the grade of the ore, the desired production rate, and the environmental regulations.

- Type of ore: The type of ore will determine the type of processing that is required. For example, if the ore is free-milling, then it can be processed using gravity separation methods. However, if the ore is refractory, then it will need to be processed using more complex methods, such as flotation.

- Grade of the ore: The grade of the ore will determine the size of the processing plant. A high-grade ore will require a smaller plant than a low-grade ore.

- Desired production rate: The desired production rate will determine the capacity of the processing equipment. A high production rate will require larger equipment than a low production rate.

- Environmental regulations: Environmental regulations will need to be taken into account when selecting processing equipment. For example, some types of equipment may require air pollution control systems.

Gold beneficiation is a complex process that requires a variety of specialized equipment. The type of equipment that is required will depend on a number of factors, including the type of ore, the grade of the ore, the desired production rate, and the environmental regulations.

In addition to the equipment described above, there are a number of other pieces of equipment that are commonly used in gold beneficiation plants. These include pumps, valves, piping, instrumentation, and electrical controls.

The selection of the right gold beneficiation equipment is critical to the success of a gold mining operation. Careful consideration of all of the factors involved will help to ensure that the chosen equipment is efficient, effective, and environmentally friendly.