Gold Ore Crushing Production Line

Gold ore is a collection of minerals with sufficient gold content that can be industrially utilized; a gold mine is a place where gold is obtained through mining operations; and a gold deposit is a pile of industrially usable gold ore formed through mineralization. There are mainly two types of gold ore: placer gold and vein gold. Gold is an important decorative item and also an ideal material for industry.

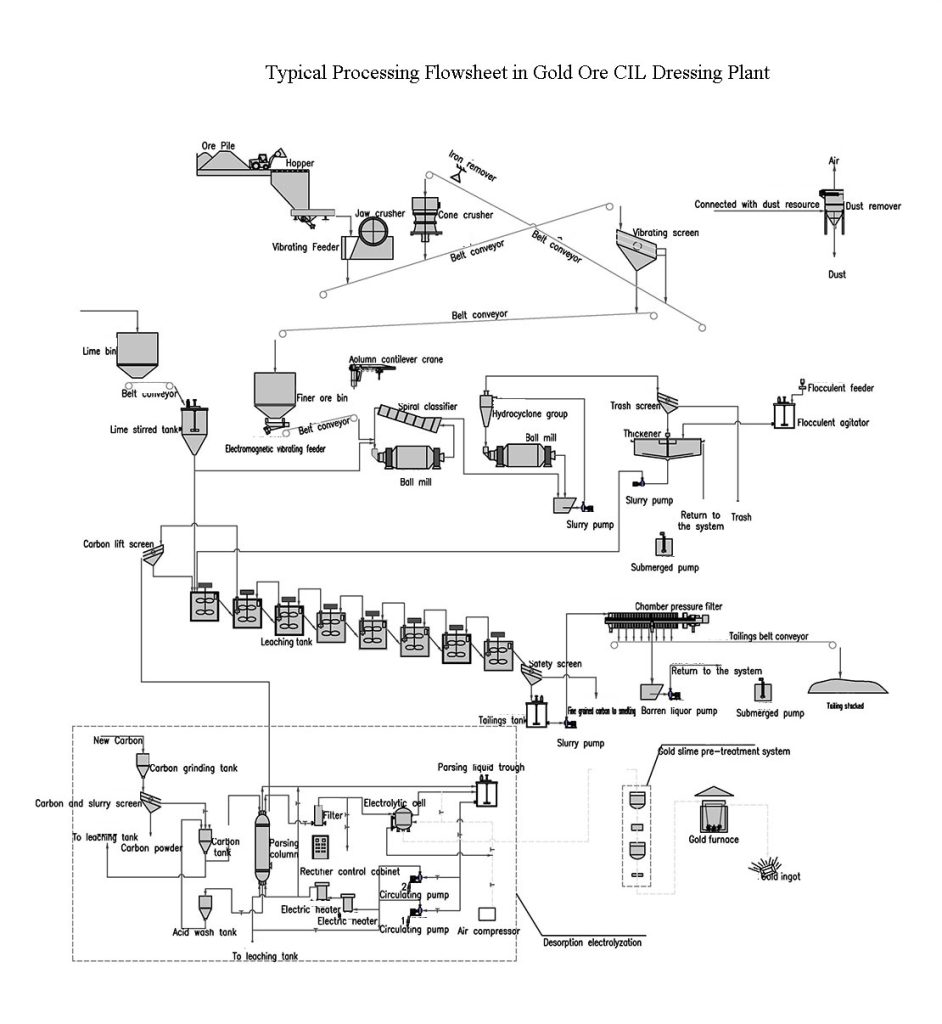

Gold ore processing production process

Gold ore processing production process mainly includes three processes: crushing, grinding, and beneficiation. In the crushing process, a three-stage closed-circuit crushing is a more modern method suitable for crushing high-hardness gold ore, which can complete the crushing and partial dissociation of the ore, thus improving the grinding efficiency in the subsequent process. In the grinding process, a two-stage one-closed grinding is an efficient grinding process that can make the gold ore more fully ground. In the beneficiation process, the more successful new processes in recent years mainly include gravity separation, amalgamation, cyanide method, flotation method, etc.

1: Crushing and screening

Large pieces of gold ore are uniformly fed into the jaw crusher or mobile jaw crushing station (primary crusher) by the vibrating feeder from the material bin for coarse crushing; the gold ore after coarse crushing is screened by the vibrating screen and then sent to the single-cylinder hydraulic cone crusher (medium crusher) for secondary crushing; the material after secondary crushing is sent to the multi-cylinder hydraulic cone crusher for fine crushing.

Jaw crushers are mainly used for medium-sized crushing of ores and large materials, and can crush materials with a compressive strength of up to 320Mpa, and are divided into coarse crushing and fine crushing. Liming Heavy Industry has PE and PEW series jaw crushers with complete product specifications, a feed size of 125mm to 1020mm, and a single machine output up to 800t/h, making it an ideal choice for primary crushing equipment. The structure is sturdy and the performance is stable: using world advanced technology, Baosteel high-quality steel, Timken bearings from the United States, heavy-duty eccentric shaft, finite element analysis technology, making its structure sturdy and performance stable, and long-term operation; high crushing ratio and high output: using heavy-duty trough wheels and flywheels, optimized jaw plates, making the crushing force greater; the “V” design makes its feed port consistent with the actual situation, the crushing chamber is deep and there is no dead zone, and the output is higher; easy to operate and energy-saving: hydraulic lubrication, wedge adjustment makes it more convenient and flexible to operate, lubrication is more convenient, and the single machine saves 15% to 30% of energy, and the system saves twice as much.

HST series single-cylinder hydraulic cone crusher is widely used in the medium and fine crushing process of metal mines such as iron ore, gold ore, and copper ore. Liming Heavy Industry’s HCS single-cylinder hydraulic cone crusher is a high-efficiency crusher designed based on American advanced technology and the performance of high-quality materials in the industry. The structure is solid and the performance is stable: it uses an integrated frame casting, heavy-duty central shaft, and both ends of the main shaft are supported, which has strong load-bearing capacity and great crushing force. It adopts advanced technology and imported Timken bearings from the United States, which makes the operation stable and has a long service life. It has automated control and is easy to operate: it uses PCL touch screen operation and hydraulic adjustment discharge mode, which makes the adjustment of the discharge port convenient, maintenance easier, and the replacement of the fixed cone more convenient and efficient, reducing downtime. It has integrated thin oil lubrication: it uses an integrated thin oil lubrication system, which is more efficient in lubrication and saves lubricating oil. It uses a wind cooling system to cool the thin oil, overcomes environmental limitations, and makes the overall process more stable and efficient.

HPT series hydraulic cone crusher is a new generation of high-efficiency hydraulic cone crusher launched based on nearly thirty years of crusher R&D experience, combined with advanced technology at home and abroad, and several generations of product development and application. Based on the traditional multi-cylinder hydraulic cone crusher’s structure of fixed main shaft and eccentric sleeve rotating around the main shaft and laminated crushing principle, HPT series has made breakthrough optimizations in equipment structure, significantly improving the equipment’s performance and crushing capacity. The supporting hydraulic lubrication system ensures reliable equipment operation, and the operation control is more intelligent and user-friendly. The upgraded structure is more efficient: based on the unique structure of the fixed main shaft and eccentric sleeve rotating around the main shaft, the transmission rotating parts and lubrication sealing structure design have been further optimized, the equipment’s load-bearing capacity is strong, the installed power is very large in the same industry, the volume is small, the efficiency is high, and the noise is low.

Tire-type mobile crushing station is widely used in the crushing process of mines. It can overcome the obstacles of crushing site, environment, complicated basic configuration, and complicated logistics brought by the customers’ crushing operations, providing customers with high-efficiency and low-cost project hardware facilities. Liming Heavy Industry’s tire-type mobile crushing station has been successfully applied in domestic and foreign mining crushing projects, playing a huge role. It is flexible and reduces costs: it is equipped with vehicle traction, compact structure, stable and sturdy, suitable for working in harsh mountain environments, and can crush materials on-site, eliminating the intermediate link of transporting materials away from the work site for crushing, greatly reducing the transportation cost of materials. It is adaptable and can be customized as needed: the crushing station can be equipped with an independent generator set, and even if the local power grid cannot be used, the machine can still operate normally. At the same time, our company can specially customize the mobile crushing station according to the customer’s site, material, particle size, and other requirements.

2: Grinding

The 0-12mm gold powder screened by the vibrating screen is evenly fed into the ball mill for grinding, and screened by the spiral classifier. The material that does not meet the requirements is sent back to the ball mill for further grinding.

Ball mill is a commonly used and efficient grinding equipment for grinding ores, such as iron ore, gold ore, copper ore, lead-zinc ore, etc., in metal beneficiation, to grind the ore to below 0.075mm for subsequent beneficiation processes. According to the different discharge methods, it can be divided into grid type and overflow type. Its grinding methods can be divided into dry and wet grinding.

The spiral classifier, also known as the classifier, is one of the beneficiation equipment. The spiral classifier uses the principle that the solid particles have different specific gravity and therefore precipitate at different speeds in the liquid to perform mechanical classification. It can classify the powder from the mill according to the filtering, and then use the spiral blade to rotate into the mill feeding port for coarse material, and discharge the filtered fine material from the overflow pipe.

3: Flotation

The gold powder that meets the beneficiation requirements is sent to the flotation machine for strong flotation to remove impurities.

The BF series flotation machine is an improved version of the SF flotation machine and is mainly used for heavy minerals such as iron ore.

The SF series flotation machine can self-absorb air and slurry. The tank body is forward-inclined and not easy to sink, which is conducive to foam backflow. It uses a double-blade impeller to have a good stirring effect on the coarse sand at the bottom.

4: Drying

The obtained gold powder is sent to the drying machine for drying to obtain gold concentrate powder.

The drying machine is a commonly used equipment in mining beneficiation, including a rotating drum. The inner drum is driven by a belt and there is hot air around the drum to evaporate the moisture. The drying drum uses the principle of reversing rotation to achieve the effect of not entangling the dried materials, so that the moisture in the materials can be removed.