European Hammer Mill

Material processing plays a vital role in numerous industries, ranging from mining and construction to agriculture and chemical processing. European Hammer Mills have emerged as a reliable and efficient solution for crushing, grinding, and pulverizing various materials. These machines are designed to handle a wide range of materials, including ores, minerals, biomass, and agricultural products.

Input Size: 0-100mm

Capacity: 0-75TPH

Material:metallurgic material, construction material, road building, and petroleum & chemical industries.

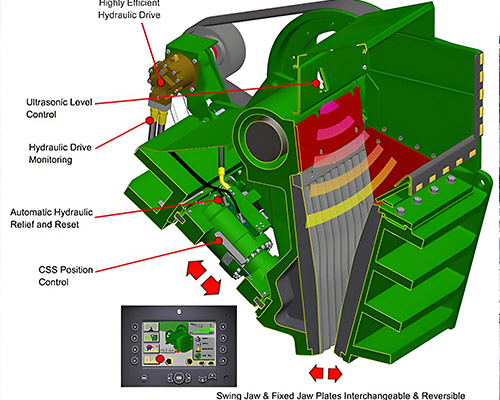

Design and Operation Principles

European Hammer Mills are characterized by their robust construction and unique operating principles. The key components include a rotor assembly, hammers, and a high-speed motor. The rotor assembly consists of a series of rotating hammers mounted on a central shaft. As the motor drives the rotor, the hammers rotate at high speed, creating impact forces that crush and grind the materials. The perforated screen located at the bottom of the grinding chamber controls the particle size of the final product.

Key Features and Advantages

European Hammer Mills offer several key features that contribute to their effectiveness and versatility. These include:

- a. High throughput capacity: European Hammer Mills are capable of processing large quantities of materials, making them suitable for industrial-scale operations.

- b. Adjustable particle size: The perforated screen allows for precise control over the particle size distribution, enabling the production of materials with specific characteristics.

- c. Versatility in material handling: European Hammer Mills can handle a wide variety of materials, from soft and friable to hard and abrasive, making them adaptable to different industrial applications.

- d. Low maintenance requirements: These machines are designed for durability and minimal maintenance, ensuring long-term reliability and cost-effectiveness.

Applications

European Hammer Mills find applications in diverse industrial sectors:

- a. Mining and ore processing: These mills are widely used for crushing and grinding ores, facilitating the extraction of valuable minerals.

- b. Construction materials: European Hammer Mills are employed in the production of aggregates and construction materials, including gravel, sand, and cement.

- c. Biomass and feed processing: These mills are utilized for grinding biomass materials such as wood chips, straw, and corn stalks, as well as processing animal feed.

- d. Chemical industry: European Hammer Mills are instrumental in reducing the particle size of chemicals, enhancing their solubility and reactivity.

Product Parameters