LUM Vertical Roller Mill

The grinding roller doesn’t contact with millstone usually, which makes abrasion little and service life longer.The LUM Vertical Roller Mill, designed and manufactured by Liming Heavy Industry, represents a groundbreaking innovation in the field of vertical roller mills. Its cutting-edge design and exceptional performance have gained widespread recognition within the industry.The grinding roller doesn’t contact with millstone usually, which makes abrasion little and service life longer.

Input Size: 0-20mm

Capacity: 5-18TPH

Material: Superfine dry powder of none-metal ores such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite and so on.

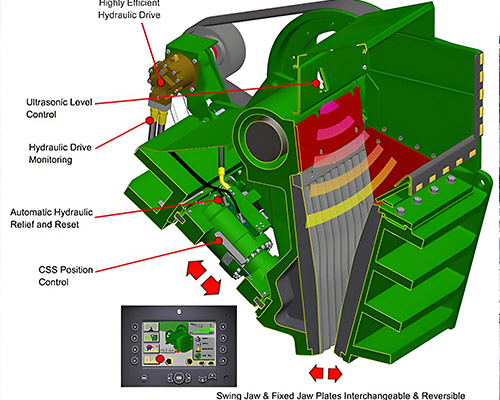

Key Features and Design

LUM Vertical Roller Mill incorporates several key features that differentiate it from traditional grinding mills. Firstly, its vertical roller structure enables efficient grinding by utilizing gravity and centrifugal force. Additionally, the mill is equipped with a specially designed roller sleeve and lining plate, ensuring uniform grinding and longer service life. The integration of multiple internal classifiers enhances the classification efficiency, resulting in finer and more precise product output.

Advantages of LUM Vertical Roller Mill

- High grinding efficiency: The mill utilizes the principle of material bed comminution, resulting in improved grinding efficiency and reduced energy consumption.

- Uniform particle size distribution: The mill’s advanced classifier ensures a uniform particle size distribution, enhancing the quality and consistency of the final product.

- Low maintenance and operational costs: The simplified structure and reliable components of the mill contribute to reduced maintenance requirements and operational costs.

- Environmental friendliness: The mill adopts a closed-circuit system, minimizing dust emissions and noise pollution, making it an environmentally friendly solution.

Sustainable Grinding Solutions

One of the critical aspects of the LUM Vertical Roller Mill is its contribution to sustainability in the mining and industrial sectors. The mill’s high grinding efficiency translates into reduced energy consumption, minimizing the carbon footprint associated with grinding operations. Moreover, its advanced classification system ensures that the grinding process produces less waste and achieves a higher utilization rate of raw materials. By promoting sustainable grinding practices, the LUM Vertical Roller Mill plays a vital role in achieving environmental conservation and resource efficiency.

Applications

LUM Vertical Roller Mill finds extensive applications across various industries, including cement, mining, metallurgy, chemical engineering, and power generation. Its versatility allows for grinding a wide range of materials, including cement clinker, slag, coal, and minerals. With its ability to produce fine and ultra-fine powders, the LUM Vertical Roller Mill caters to the increasing demand for high-quality products in diverse industrial sectors.

Product Parameters