MW Series Micro Powder Mill

MW Series Micro Powder Mill has emerged as a game-changing grinding equipment in many industries. It plays a crucial role in the production of ultra-fine powder materials and has been widely used in mining, construction, metallurgy, and chemical industries. MW Series Micro Powder Mill is equipment designed for customers who need to make ultra-fine powder. This machine is equipped with efficient pulse dust collector and muffler, which can reduce dust and noise. And the whole production won’t take effect on environment.

Input Size: 0-20mm

Capacity: 0.5-30TPH

Material: Chemical Industry, paint, cosmetics, medicine, food additive,etc.

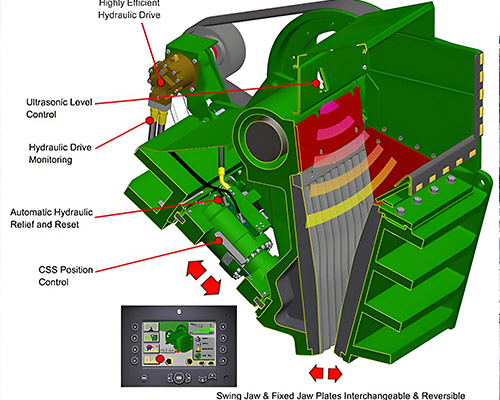

Key Features and Working Principle:

MW Series Micro Powder Mill incorporates several key features that contribute to its efficiency. These include a high-speed rotor with grinding rollers, a powerful grinding system, and an advanced classification system. The mill operates based on the principle of impact and grinding, where the materials are fed into the grinding chamber and crushed by the rotating grinding rollers. The crushed materials are then transported to the classifier, which separates the fine powder from the coarse particles.

Advantages and Benefits:

MW Series Micro Powder Mill offers numerous advantages over traditional grinding mills. Firstly, it has a high grinding efficiency, allowing for the production of ultra-fine particles with reduced energy consumption. Secondly, the mill has a wide range of application capabilities, making it suitable for grinding various materials, including minerals, chemicals, and non-metallic ores. Additionally, the MW Series Micro Powder Mill has a compact structure, low maintenance requirements, and easy operation, which further enhance its practicality.

Applications:

MW Series Micro Powder Mill finds extensive applications in various industries. In the mining industry, it is used for grinding minerals and ores, such as limestone, gypsum, and talc. In the chemical industry, the MW Series Micro Powder Mill is employed for processing chemicals and pigments. Furthermore, it is utilized in the construction industry for grinding materials like cement clinker and concrete.

Performance Metrics and Future Prospects:

The performance of the MW Series Micro Powder Mill can be evaluated based on several key metrics, including grinding efficiency, energy consumption, and product fineness. Ongoing research and development efforts focus on improving the mill’s performance, optimizing its operation, and reducing environmental impacts. Future prospects include the integration of advanced control systems and automation technologies to enhance productivity, precision, and sustainability.

Product Parameters