TGM Trapezium Mill

TGM Trapezium Mill is an innovative grinding mill developed by a renowned manufacturer in response to the growing demand for advanced grinding solutions in various industries. It combines years of research, development, and practical application to deliver a high-performance milling machine capable of tackling a wide range of materials. TGM Super Pressure Trapezium Mill adopts five proprietary technologies including trapezium working surface, flexible connection, roller linked pressure boost, etc.

Input Size: 0-35mm

Capacity: 3-22TPH

Material:Cement, Coal, power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

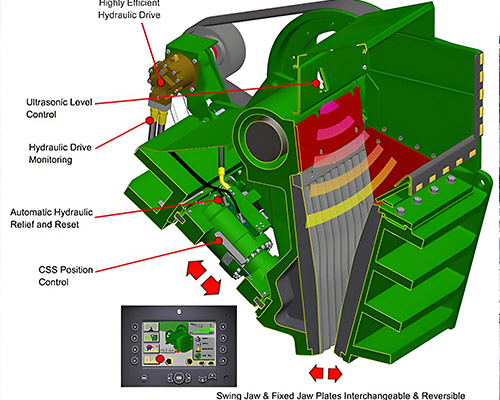

Key Features and Design

TGM Trapezium Mill incorporates several key features that enhance its grinding capabilities. These features include a patented trapezoidal working surface, flexible connection, multiple rollers, and a high-efficiency impeller. The paper examines each of these features in detail, highlighting their significance in achieving superior grinding performance.

Working Principle

TGM Trapezium Mill operates on the principle of material being fed into the center of the mill’s grinding table. Under the action of centrifugal force, the material is evenly distributed to the grinding rollers and rings. As the grinding rollers rotate, they crush, grind, and pulverize the material into fine powder. The airflow generated by the high-speed rotation of the mill’s blower carries the ground material into the classifier, where it is separated based on particle size.

Advantages and Benefits

- 1. High Grinding Efficiency: The TGM Trapezium Mill employs a unique grinding mechanism that ensures high grinding efficiency and reduced energy consumption, resulting in significant cost savings.

- 2. Wide Range of Applications: The mill can effectively grind various materials, including limestone, gypsum, dolomite, barite, talc, and coal, making it versatile for use in different industries such as mining, construction, and chemical engineering.

- 3. Excellent Product Quality: The mill’s advanced grinding technology and efficient separator system contribute to the production of fine, uniform particles with controlled particle size distribution, enhancing product quality.

- 4. Low Operation and Maintenance Costs: The mill’s robust design, durable components, and simplified maintenance procedures minimize operation and maintenance costs, ensuring long-term economic benefits.

Applications

TGM Trapezium Mill finds wide-ranging applications in diverse sectors, including mining, metallurgy, construction, chemical engineering, and cement production. This section explores these applications in detail, illustrating how the mill’s capabilities contribute to increased productivity, cost-effectiveness, and product quality.

Case Studies

To further exemplify the effectiveness of the TGM Trapezium Mill, this section presents real-world case studies from different industries. These case studies provide practical insights into the mill’s performance, showcasing its ability to handle various materials, achieve optimal grinding results, and deliver substantial economic benefits.

Future Developments and Conclusion

As with any technological innovation, the TGM Trapezium Mill is subject to continuous research and development efforts. This section discusses potential future developments and improvements in the design and performance of the mill. Furthermore, the paper concludes by emphasizing the significance of the TGM Trapezium Mill as a cutting-edge solution for efficient grinding and its potential to revolutionize the industry.

Product Parameters