Marble Crushing and Grinding Process

Marble is a common building material with beautiful appearance, wear resistance, acid and alkali resistance, and aging resistance. With the development of society and the increasing demand for quality of life, the demand for marble is growing. Therefore, crushing and grinding marble into high-quality marble powder through processing has broad application prospects.

Basic principles of marble crushing and grinding powder processing

The basic principles of marble crushing and grinding powder processing are to process the marble raw materials into a powder product that meets the requirements through crushing, screening, grinding, and packaging processes. Crushing is to coarsely crush the marble raw materials with a crusher to meet the requirements for further processing; screening is to separate the coarse crushed marble particles according to their size for subsequent processing; grinding is to finely grind the screened marble particles with a grinding machine to achieve the required powder fineness; and packaging is to package the ground marble powder for sale or storage.

Equipment for marble crushing and grinding powder processing

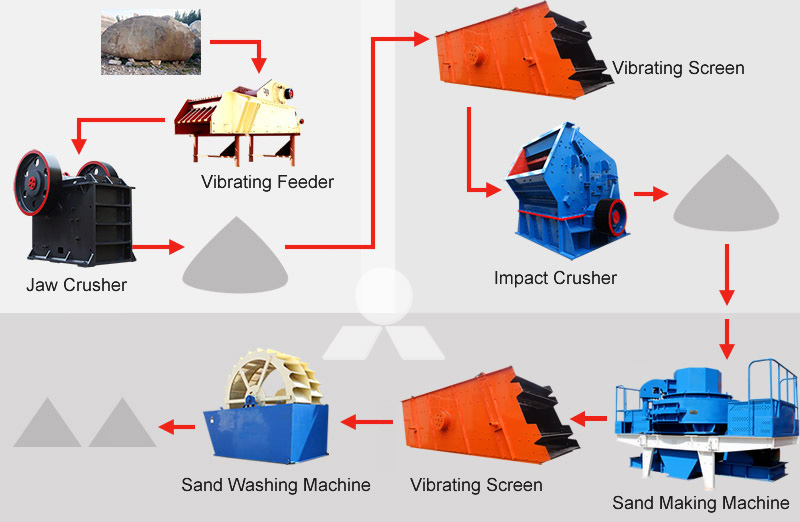

The equipment for marble crushing and grinding powder processing mainly includes crushers, screening machines, grinding machines, and packaging machines. Among them, crushers mainly include hammer crushers, jaw crushers, and cone crushers; screening machines mainly include vibrating screens, rotating screens, and linear screens; grinding machines mainly include ball mills, grinders, and high-pressure suspension roller mills; packaging machines mainly include automatic packaging machines and manual packaging machines.

Process flow of marble crushing and grinding powder processing

The process flow of marble crushing and grinding powder processing is as follows:

Raw material feeding → Crushing → Screening → Grinding → Packaging

The raw materials enter the crusher through the feeding port, are coarsely crushed by the crusher, and then screened by the screening machine to separate the marble particles that meet the requirements. The screened particles are then sent to the grinding machine for grinding to achieve the required powder fineness. Finally, the ground marble powder is packaged by the packaging machine.

Application fields of marble crushing and grinding powder processing

The products of marble crushing and grinding powder processing are widely used in the fields of building materials, chemical industry, plastics, paint, coating, papermaking, rubber, plastics, glass, etc. In the field of building materials, they are mainly used in the production of marble products such as floor tiles, wall tiles, and marble sculptures. In the chemical industry, they are mainly used in the production of fillers, coatings, etc. In the plastics industry, they are mainly used in the production of reinforced fillers.

Marble crushing and grinding powder processing is an important industry with broad application prospects. Through the introduction of the basic principles, equipment, process flow, and application fields of marble crushing and grinding powder processing, we can understand the current situation and future development trends of this industry. In future work, we should focus on technological innovation, improve production efficiency and product quality, and make greater contributions to the development of marble crushing and grinding powder processing.