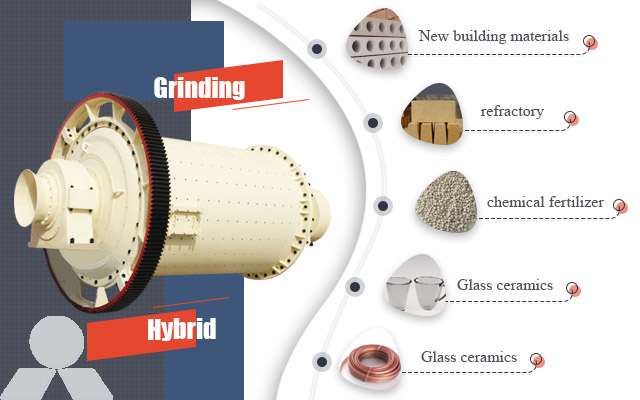

Types of ball-mills for marble grinding processing in Egypt

Egypt has a rich history when it comes to the use of marble. The use of this exquisite stone dates back to ancient times, with the construction of famous monuments like the Pyramids and the Sphinx. Today, marble continues to be a prominent material in Egyptian architecture and art. To shape and enhance marble’s natural beauty, various grinding and processing techniques are employed. One of the key tools in this process is the ball mill. In this article, we will explore the different types of ball mills used for marble grinding processing in Egypt.

- Traditional Ball Mills:

- Traditional ball mills are widely used in the marble processing industry in Egypt. They consist of a rotating horizontal cylinder containing marble pieces and grinding media (balls or rods). As the cylinder rotates, the grinding media crush and grind the marble into the desired fine powder. These ball mills are often used for medium to large-scale marble processing operations.

- Planetary Ball Mills:

- Planetary ball mills are a more advanced type of ball mill that can be used for precise marble grinding. They consist of several grinding jars that rotate on their own axis while also orbiting around a common center. This motion provides a high level of energy input, resulting in faster and finer grinding. Planetary ball mills are often used in laboratories and research facilities for small-scale marble processing.

- Vibratory Ball Mills:

- Vibratory ball mills are another option for marble grinding in Egypt. These mills use vibration to move the grinding media, creating a uniform and consistent grinding action. Vibratory ball mills are known for their efficiency and the ability to achieve very fine particle sizes. They are suitable for both small and large-scale marble processing operations.

- Ball Mill with Classifier:

- In some cases, a classifier is added to the ball mill to control the particle size distribution of the ground marble. This setup is often used when specific particle size requirements are needed for certain applications. Classifiers help ensure that the finished marble product meets the desired specifications.

- Stirred Media Mills:

- While not as common as the other types of ball mills, stirred media mills are sometimes used for marble grinding. They use a rotating stirrer to agitate the grinding media and marble particles. This agitation provides a more efficient grinding process, making them suitable for fine and ultra-fine grinding of marble.

In Egypt, marble grinding and processing are integral to the country’s cultural and economic heritage. Various types of ball mills are employed to achieve the desired marble powder fineness, depending on the scale of the operation and the specific requirements. Traditional ball mills are widely used, while more advanced options like planetary and vibratory ball mills offer increased precision and efficiency. Additionally, the use of classifiers and stirred media mills allows for even greater control over the final product’s quality. The choice of ball mill type depends on the scale and objectives of marble processing in this historically significant industry.