Mobile Impact Crusher

Mobile Impact Crusher has revolutionized the way quarrying and construction activities are carried out. Its mobility, compact size, and ability to process various materials on-site make it an essential tool for professionals in these industries. Mobile Impact Crusher can process medium hard stones, and final products can be used in road, bridge, construction and water conservancy, etc. industries. As one process of crushing work, mobile Impact Crusher can meet different requirements about capacity and output size by changing models.

Input Size: 52-360 mm

Capacity: 20-450 t/h

Applicable Material: mining, quarry, mixing and batching plant, road and building construction, highway, railway and subway, and water conservancy.

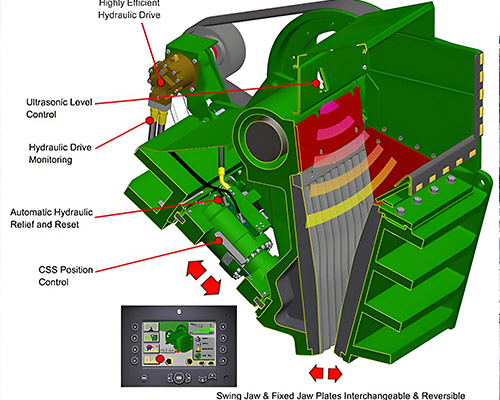

Design and Working Principles

Mobile Impact Crusher is designed as a compact and self-contained unit, equipped with a powerful impact crusher, vibrating feeder, screening system, and conveyor belts. It operates by feeding the material into the crusher, where high-speed rotating hammers impact and break it down into smaller sizes. The crushed material is then screened to separate the desired product.

Flexibility and Mobility

One of the key advantages of the Mobile Impact Crusher is its exceptional mobility. It can be easily transported to different job sites, reducing the need for multiple stationary crushers. This mobility allows operators to process materials directly at the extraction site, eliminating the need for costly transportation and reducing project timelines.

Versatility and Efficiency

Mobile Impact Crusher can handle a wide range of materials, including concrete, asphalt, limestone, and other aggregates. Its versatile nature allows for quick adjustments, enabling the production of various product sizes and specifications. This adaptability contributes to higher operational efficiency and ensures optimal resource utilization.

Environmental Benefits

Mobile Impact Crusher offers significant environmental benefits compared to traditional crushing methods. By processing materials on-site, it reduces the need for transportation, resulting in lower carbon emissions and reduced traffic congestion. Additionally, the use of advanced dust suppression and noise reduction technologies minimizes the impact on local ecosystems and communities.

Productivity and Cost-effectiveness

Mobile Impact Crusher enhances productivity by eliminating the need for manual labor and multiple equipment setups. Its automated processes and efficient crushing capabilities result in faster project completion and reduced labor costs. The versatility and mobility of the crusher contribute to overall cost-effectiveness by maximizing operational uptime and minimizing equipment maintenance.

Case Studies and Success Stories

This section presents case studies and success stories from industry professionals who have adopted the Mobile Impact Crusher in their operations. These real-world examples demonstrate its positive impact on project timelines, cost savings, and overall operational efficiency.

Future Developments and Challenges

As technology continues to evolve, the Mobile Impact Crusher is expected to undergo further advancements. This section discusses potential future developments, such as improved automation, enhanced energy efficiency, and integration with emerging technologies. It also addresses the challenges associated with widespread adoption, including regulatory compliance and operator training.

Product Parameters