Mobile Primary Jaw Crusher

Mobile primary jaw crusher has emerged as a revolutionary solution in the field of mineral processing and quarrying. In the world of mining, quarrying, and construction, the demand for efficient and flexible crushing solutions is growing rapidly. The mobile primary jaw crusher is a game-changer in this context, as it offers a unique combination of mobility, adaptability, and high crushing capacity. Since the late 20th century, tens of thousands of Mobile Primary Jaw Crushers equipped with quality jaw crushers have been installed all over the world. From single machine running to multiterminal online application, Mobile Primary Jaw Crusher can satisfy customers’ diversified demand.

Input Size: 0-930 mm

Capacity: 15-500 t/h

Applicable Material: mining, quarry, mixing and batching plant, road and building construction, highway, railway and subway, and water conservancy.

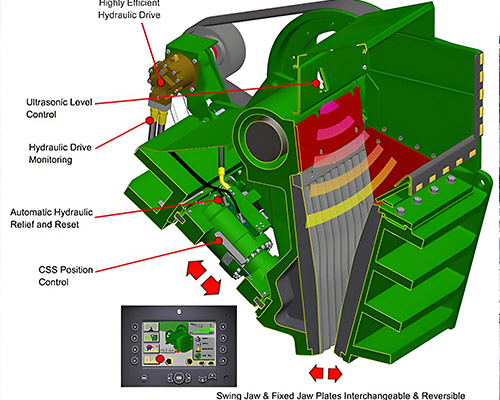

Key Features:

The mobile primary jaw crusher is characterized by several key features that contribute to its exceptional performance:

1. Mobility:

The primary jaw crusher is mounted on a mobile chassis, allowing it to be easily transported between job sites. This mobility eliminates the need for costly transportation equipment and reduces downtime between crushing operations.

2. Adaptability:

The crusher’s design enables it to handle various types of materials, including hard rocks, ores, and construction waste. With adjustable jaw settings, it can produce different sizes of crushed material, making it suitable for a wide range of applications.

3. High Crushing Capacity:

Equipped with a powerful jaw crusher, the mobile primary jaw crusher can deliver high crushing capacity and productivity. Its large feed opening and aggressive crushing action ensure efficient reduction of materials, resulting in higher throughput and lower operating costs.

4. Robust Construction:

Designed to withstand demanding working conditions, the mobile primary jaw crusher is built with a sturdy frame and reinforced components. This robust construction enhances its durability and longevity, even in the harshest environments.

5. Eco-Friendly Design:

The mobile primary jaw crusher incorporates eco-friendly features such as low emissions and noise levels. Advanced technology, including hybrid power options, reduces fuel consumption and minimizes environmental impact, aligning with sustainable development goals.

Applications:

The versatility of the mobile primary jaw crusher makes it suitable for a wide range of applications:

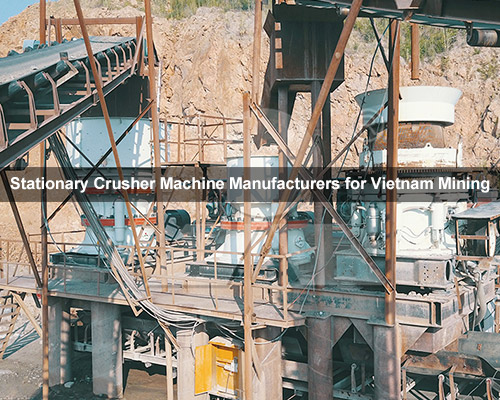

1. Quarrying and Mining:

In quarrying and mining operations, the crusher efficiently processes various materials, including limestone, granite, and basalt. Its mobility allows it to move closer to the extraction site, minimizing transportation costs and enhancing productivity.

2. Construction and Demolition Waste Recycling:

The mobile primary jaw crusher is an ideal choice for recycling applications. It can crush and process concrete, asphalt, and other construction waste, transforming them into valuable aggregates for reuse in construction projects.

3. Infrastructure Development:

The crusher’s mobility and high crushing capacity make it an excellent tool for infrastructure development projects. It can handle large volumes of materials, such as rocks and gravel, for road construction, railway ballast, and concrete production.

Product Parameters