Mobile Secondary Cone Crusher

In recent years, the demand for aggregates and minerals has witnessed a significant surge, necessitating the development of efficient crushing solutions. The Mobile Secondary Cone Crusher represents a remarkable advancement in mobile crushing technology, designed to cater to the growing requirements of the mining and construction industries.

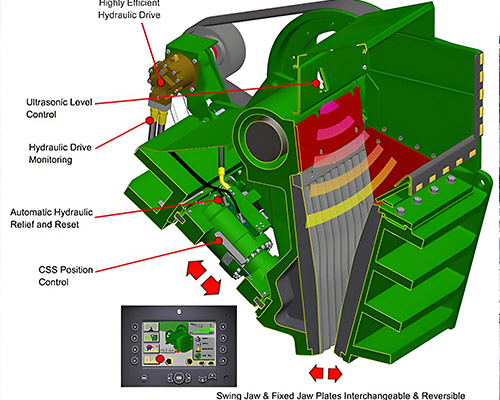

Mobile Secondary Cone Crusher is a portable crushing unit that combines the functionalities of a cone crusher and a screening plant. It is capable of producing high-quality aggregates for various applications. The crusher utilizes a cone-shaped crushing chamber, where rocks are compressed between a mantle and a concave. This design ensures efficient and uniform crushing, resulting in superior product quality.

Input Size: 0-360 mm

Capacity: 45-430 t/h

Applicable Material: mining, quarry, mixing and batching plant, road and building construction, highway, railway and subway, and water conservancy.

Key Features and Benefits

1. Mobility and Versatility

The mobile nature of the Secondary Cone Crusher allows it to be easily transported between different job sites. It eliminates the need for extensive infrastructure development, enabling faster setup and dismantling. Additionally, the crusher’s versatility enables it to handle a wide range of materials, including hard and abrasive rocks, making it suitable for diverse applications.

2. Enhanced Efficiency and Productivity

The Secondary Cone Crusher incorporates advanced technologies, such as hydraulic systems and intelligent control, to optimize crushing performance. The automated features, such as adjustable settings and real-time monitoring, ensure consistent product size and reduce downtime. Moreover, the high crushing capacity and rapid processing speed of the crusher contribute to improved operational efficiency and increased productivity.

3. Cost-Effective Operation

Mobile Secondary Cone Crushers offer cost-effective crushing solutions due to their energy-efficient design and reduced maintenance requirements. The use of advanced automation minimizes human intervention and maximizes operational uptime, resulting in lower operating costs. Additionally, the mobile nature of the crusher reduces transportation expenses and allows for flexible deployment, optimizing overall operational expenses.

Applications

Mobile Secondary Cone Crusher finds extensive applications in the mining and construction industries. It is used for the production of aggregates for road construction, railway ballast, concrete and asphalt production, and various other construction materials. Its ability to operate in different terrains and handle a variety of materials makes it an ideal choice for both primary and secondary crushing operations.

Product Parameters