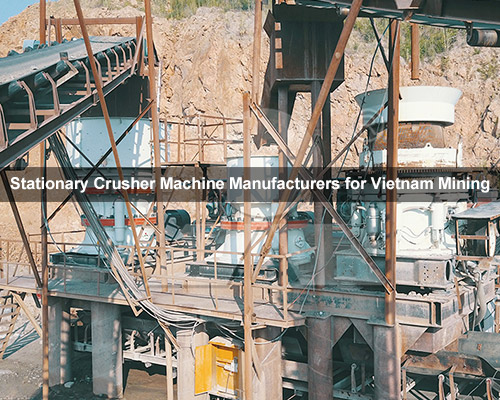

SMP Modular Crushing Production Line

SMP (Stationary Modular Plant) crushing production line of Liming Heavy Industry is a type of equipment used in the mining and construction industries to process and crush various types of raw materials into smaller, more manageable sizes. This type of production line is designed for stationary use and is composed of modular components that can be easily configured and customized to meet specific production requirements.Additionally, it boasts high overall reliability and conforms to relevant international safety design standards. It also eliminates the need for large-scale concrete foundations, making it more environmentally friendly.

Applications: quarry, metallurgical mines, building materials, highways, railways, water conservancy, chemical industry and other industries are mainly used for crushing, screening, shaping, sand making and construction waste for various stones.

Here’s an overview of the key components and features typically found in an SMP modular crushing production line:

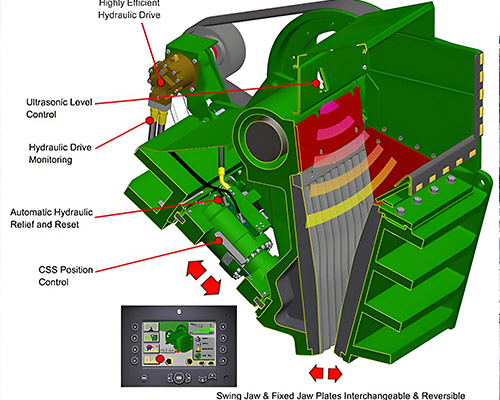

- Primary Crusher: This is the first stage of the crushing process, where large raw materials are fed into the crusher to reduce their size. Common types of primary crushers include jaw crushers, gyratory crushers, and impact crushers.

- Secondary Crusher: In some cases, a secondary crusher may be used to further reduce the size of the crushed material. Common secondary crushers include cone crushers and impact crushers.

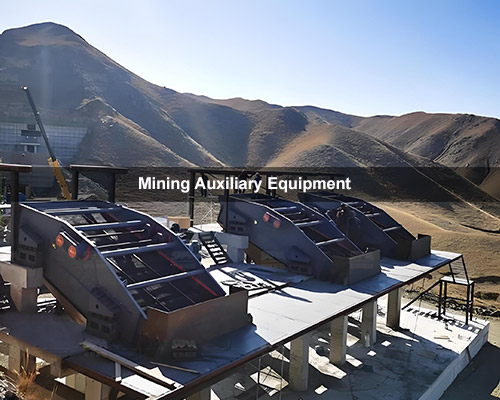

- Screening Equipment: Screens are used to separate the crushed material into different sizes. Vibrating screens or deck screens can be part of the production line to classify the materials.

- Conveyor Systems: Conveyor belts or systems are used to transport the crushed materials between different stages of the production line, such as from the primary crusher to the secondary crusher or from the crushers to the stockpile.

- Feed Hopper: A feed hopper is used to load raw materials into the primary crusher. It can be equipped with a vibrating feeder to regulate the flow of material into the crusher.

- Control Panel: The control panel is the central hub for operating and monitoring the entire crushing production line. It allows operators to adjust settings, track production metrics, and ensure the safe and efficient operation of the equipment.

- Modular Design: The key feature of an SMP modular crushing production line is its modular design. This means that the components are pre-manufactured and can be easily assembled and disassembled. This flexibility allows for quick installation, easy maintenance, and scalability as production needs change.

- Dust Suppression System: To control dust emissions, especially in mining operations, a dust suppression system may be integrated into the production line. This system helps reduce environmental impacts and improve the safety of the working environment.

- Safety Features: Crushing equipment typically includes various safety features to protect operators and prevent accidents. These features may include emergency stop buttons, safety guards, and warning systems.

- Durable Construction: The equipment used in an SMP modular crushing production line is built to withstand the rigors of heavy-duty operation in harsh environments, such as mining sites and quarries.

Overall, an SMP modular crushing production line provides a flexible and efficient solution for processing raw materials, whether for the production of aggregates, building materials, or minerals. Its modular nature allows for customization to suit specific production needs, making it a versatile choice for various industries.

Advantage of SMP modular crushing production line

- There is only a small work amount at site, a small amount of concrete or no concrete foundation.

- All modules are configured with a sled support, no anchor bolt design.

- Can be easily installed on the spot.

- Easy debugging, optional electrical control of different configurations.

- Short delivery time and fast delivery.

- Free matching can also be used to upgrade and expand existing old production lines.

- The larger warehouse volume, and at the same time, it is equipped with a mid -buffer warehouse to provide stable materials for crusher, achieve continuous production, and provide conditions to improve efficiency.

Specifications – Technical DataPrinciple